So a bit of an update;

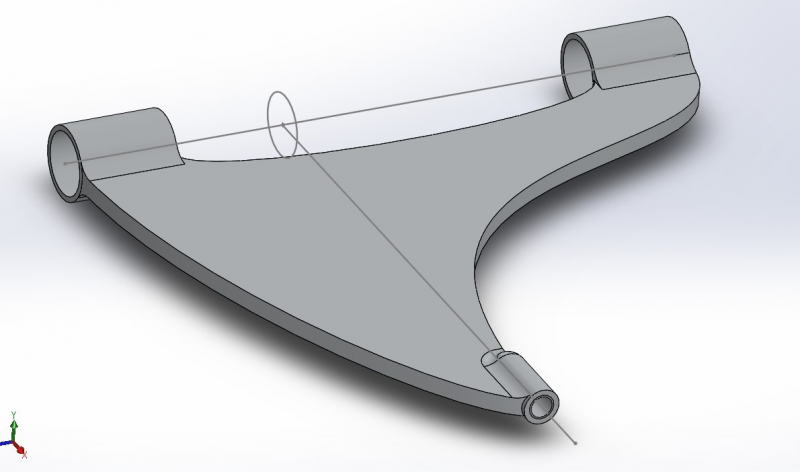

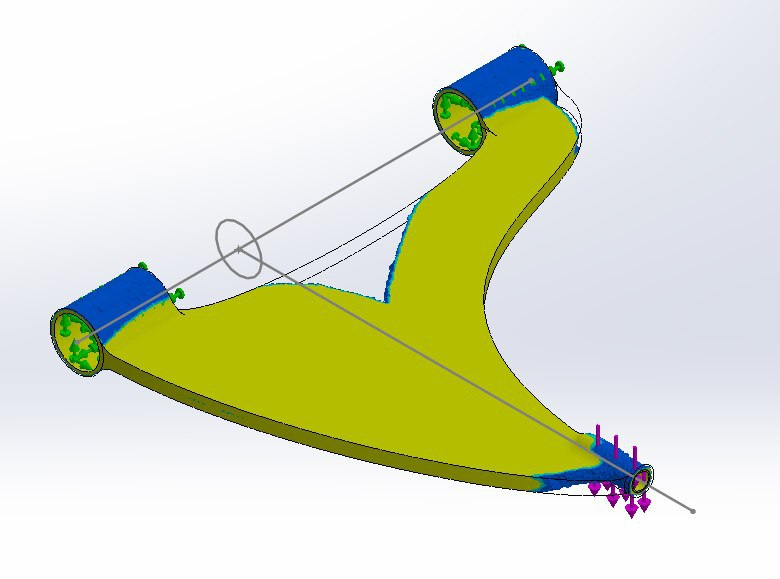

I've decided to delay the material testing and do another experiment at the same time. While hunting for ball joints I came across a place in Queensland that refurbishes old ball joints. I had a reasonably long chat to the guy who does it and am going to give it a whirl. My plan is to send the 4 arms I've got off the car in to be refurbished and fit them to the car, then resume the material testing on the arms that come off the car. I'll still be able to do the CAD work and measure the existing arms for fitment in the meantime. I've found a metrology lab in Perth with a CMM and am getting some quotes on getting accurate dimensioning of the mounting positions and bushing fitment.

Anyway back to the ball joints...

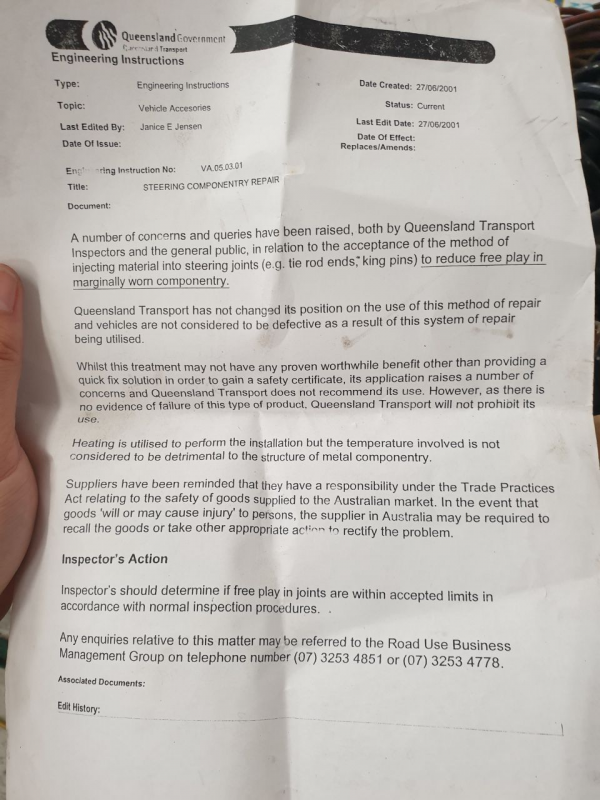

In principle the process makes a lot of sense, you inject the ball joint with a thermosetting plastic (a proper engineering plastic like what would've been used in the joint in the first place,

you can look at how serious plastics get over here) to fill any play, regrease and let the part do its thing. This isn't economical to do for a car with replaceable joints, as there is a bit of labour costs in getting the joint ready which makes it cost the same as replacing the joint. The process is basically only used on trucks and classic cars. So long as the play isn't to the point that it is metal on metal, it should be as resilient as the OEM plastic bushing (so for our cars, 50 000km-100 000km). If it does get to the point that the metal is pitted I was told that the injected plastic will wear quickly.

I'd never heard of a process like this before investigating the ball joints for this car, but it turns out its accepted as safe and operable in Australia, and he has approval from the Queensland Department of Transport. Apparently there was a case or complaint brought by a truck parts supplier to try and get it stopped but the process was deemed safe. The business owner has kindly said he'll send me over a copy of the documents.

So there may be a less costly alternative for people who haven't worn out the joints yet. I'll be running my car with the arms repaired while I work on making a new set, so I'll report in with how that goes!