lambertius

Banned

- Messages

- 341

So I've got the dreaded control arm play in the rear end of my car. This makes me sad.

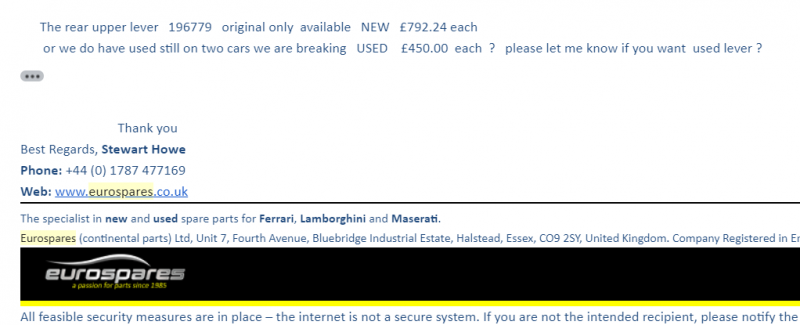

Unfortunately the costs for replacements are very unreasonable. The pattern part from Eurospares is only available on the lower arm, and with the exchange rate being double that adds up to way too much for a part that will fail again in the future. If you're going to make a disposable part it should have a disposable price.

I spoke with New Model Wreckers in Sydney and bought some used arms from them, but unfortunately they were also in poor condition. They kindly refunded the costs and left me with the parts. I spoke with Trident spares but unfortunately that pesky dollarydoo makes it hard to justify buying used parts, and then, again, you don't really know if there is play until the joint is loaded up so there is a lot of effort involved in swapping the part before you really know and since they have a 100% failure rate I'm really only delaying the inevitable even if I do get a good one.

This has lead me to the only logical conclusion, which is to put in a fairly unreasonable amount of effort designing the whole part again from scratch to include a replaceable ball joint. This allows me a chance to remove one of the engineering level problems with the car and save some money fixing it (it is kind of nuts that this should be cheaper).

So what do I do now? I take you on my journey from start to finish, success or failure.

Step 1: OEM Material Grade Identification

As I've been kindly left with the defective parts, I have ample amounts of material sample which can be tested. The process for this requires specialised equipment and is simply not possible to do on your own. The best way to do this is to engage a specialised lab, I'll be using SGS though ALS is also capable and both have an international presence. Most universities also have the same capabilities and a degree of commercialisation so it should be possible to use their services as well.

SGS will be conducting two categories of tests, chemical analysis and surface (hardness) testing. I could also elect for tensile strength if they're unable to determine the material grade from those tests.

Chemical analysis involves dissolving a metal sample in hydrofluric acid or aqua regia, a few steps preparing in between, and then running the sample through a machine called an ICP-OES - you can read all about it here. This will tell me with certainty what the makeup of the alloy is. As part of this service SGS will identify the alloy grade so that I can literally look it up in a catalogue. We're anticipating a Magnesium/Aluminium alloy.

Surface testing will measure surface hardness in Vickers, Rockwell and Brinell. This will identify if there were any surface treatments and the casting or die method used in manufacture.

Samples won't be sent off till late next week and will take some time to process but I will update everyone with the findings in a few weeks.

The goal of this step is to identify the material for modelling and subsequent FEA of the OEM part and identification and FEA of a comparable billet grade to ensure compliance in step 3. You can read about FEA here.

Step 2: Copy the Part

Step 3: Analyse the Part

Step 4: Identify a suitable Ball Joint and repeat Step 3

Step 5: Make it

Step 6: Compliance Approval (Maybe)

Unfortunately the costs for replacements are very unreasonable. The pattern part from Eurospares is only available on the lower arm, and with the exchange rate being double that adds up to way too much for a part that will fail again in the future. If you're going to make a disposable part it should have a disposable price.

I spoke with New Model Wreckers in Sydney and bought some used arms from them, but unfortunately they were also in poor condition. They kindly refunded the costs and left me with the parts. I spoke with Trident spares but unfortunately that pesky dollarydoo makes it hard to justify buying used parts, and then, again, you don't really know if there is play until the joint is loaded up so there is a lot of effort involved in swapping the part before you really know and since they have a 100% failure rate I'm really only delaying the inevitable even if I do get a good one.

This has lead me to the only logical conclusion, which is to put in a fairly unreasonable amount of effort designing the whole part again from scratch to include a replaceable ball joint. This allows me a chance to remove one of the engineering level problems with the car and save some money fixing it (it is kind of nuts that this should be cheaper).

So what do I do now? I take you on my journey from start to finish, success or failure.

Step 1: OEM Material Grade Identification

As I've been kindly left with the defective parts, I have ample amounts of material sample which can be tested. The process for this requires specialised equipment and is simply not possible to do on your own. The best way to do this is to engage a specialised lab, I'll be using SGS though ALS is also capable and both have an international presence. Most universities also have the same capabilities and a degree of commercialisation so it should be possible to use their services as well.

SGS will be conducting two categories of tests, chemical analysis and surface (hardness) testing. I could also elect for tensile strength if they're unable to determine the material grade from those tests.

Chemical analysis involves dissolving a metal sample in hydrofluric acid or aqua regia, a few steps preparing in between, and then running the sample through a machine called an ICP-OES - you can read all about it here. This will tell me with certainty what the makeup of the alloy is. As part of this service SGS will identify the alloy grade so that I can literally look it up in a catalogue. We're anticipating a Magnesium/Aluminium alloy.

Surface testing will measure surface hardness in Vickers, Rockwell and Brinell. This will identify if there were any surface treatments and the casting or die method used in manufacture.

Samples won't be sent off till late next week and will take some time to process but I will update everyone with the findings in a few weeks.

The goal of this step is to identify the material for modelling and subsequent FEA of the OEM part and identification and FEA of a comparable billet grade to ensure compliance in step 3. You can read about FEA here.

Step 2: Copy the Part

Step 3: Analyse the Part

Step 4: Identify a suitable Ball Joint and repeat Step 3

Step 5: Make it

Step 6: Compliance Approval (Maybe)