Thought I would throw out an update.

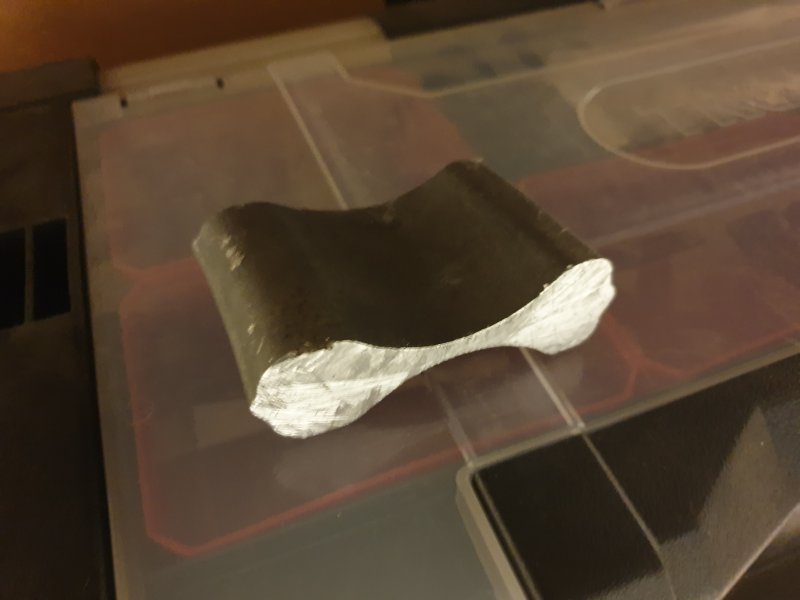

Despite some issues with the plague getting in the way of everything, I managed to get my co-ordinate geometry report for both the upper and lower control arms. If I'm lucky I'll be able to get a material sample off on Tuesday, if not it will be a month before I can get another chance.

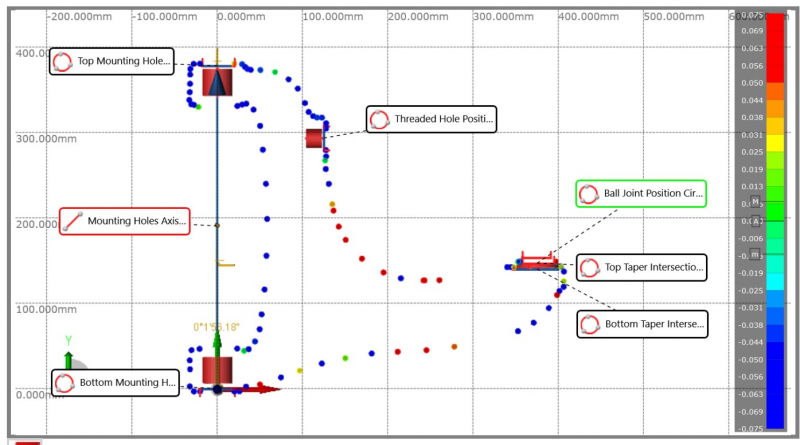

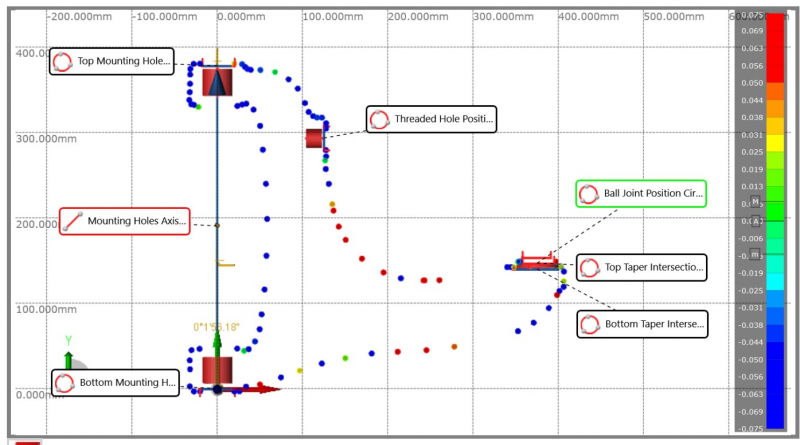

So below are some screen shots of the report I received. It is a bit low tech these days, but a lot cheaper than 3D scanning and for simple shapes it is good enough.

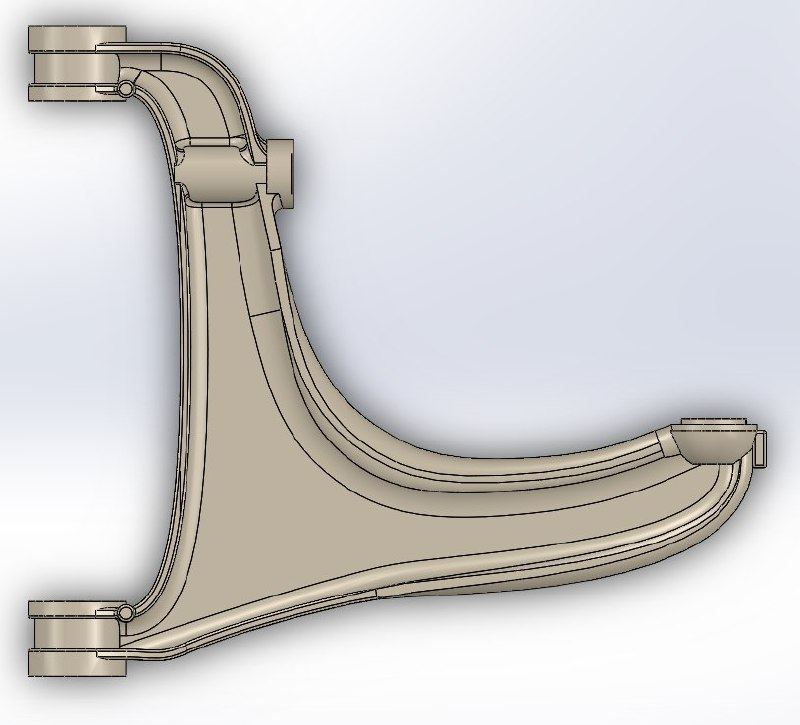

You get a co-ordinate system with a bunch of data points. Further on in the report some of the specific call outs that are named are given specific values that I can apply. Most important is that I'm given the centre co-ordinates for all the mounting points.

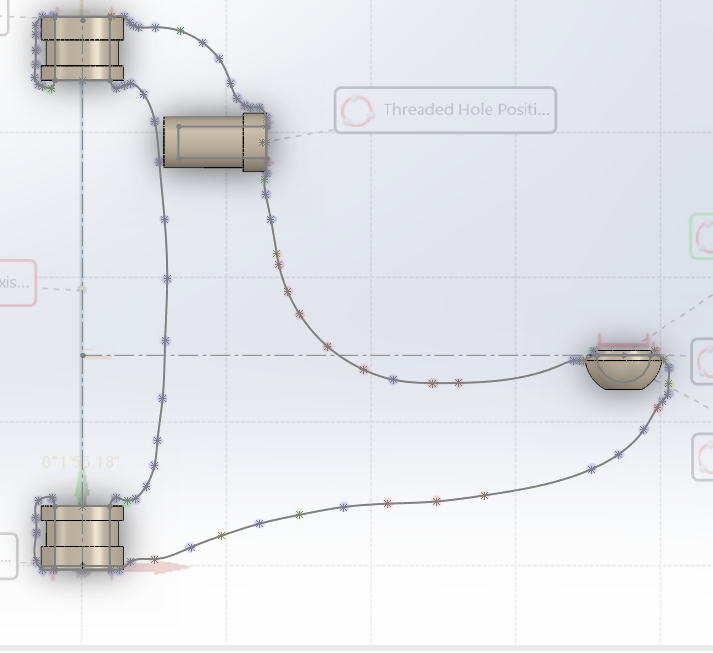

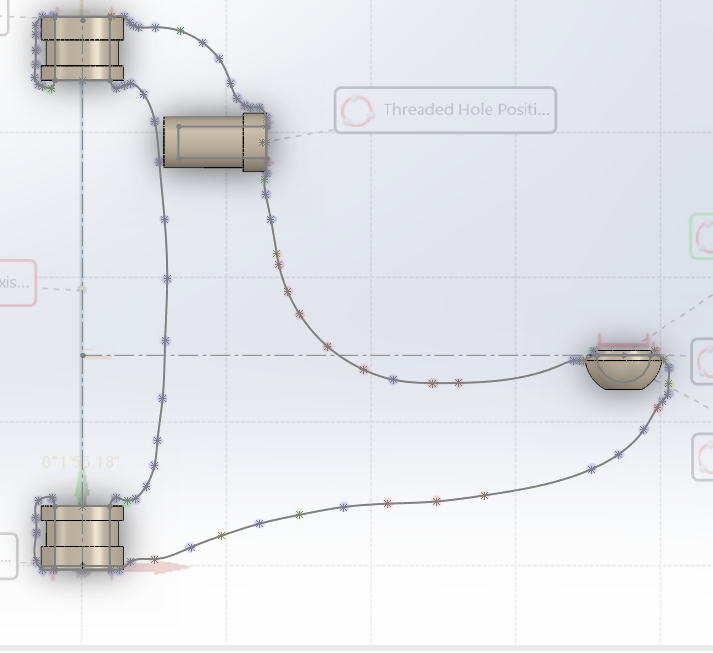

From this I can generate exact mounting positions in CAD

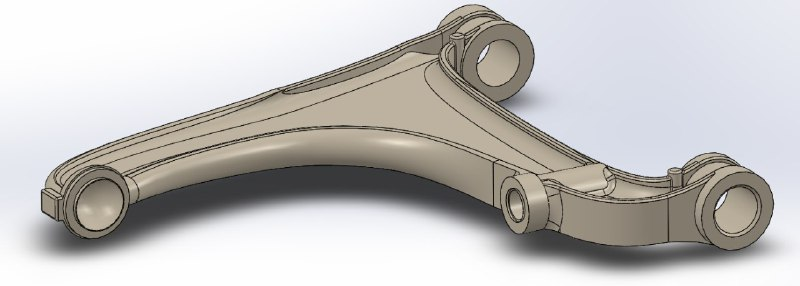

I can choose how to join those points in anyway that I want. For my own arms I'll be changing the sizing of the tie rod, ball joint and bushing points so that I can just pull some common catalogue parts.

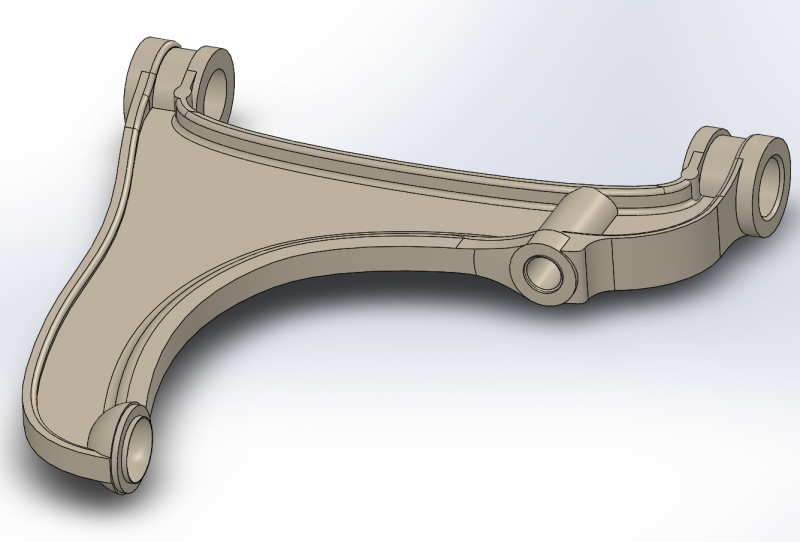

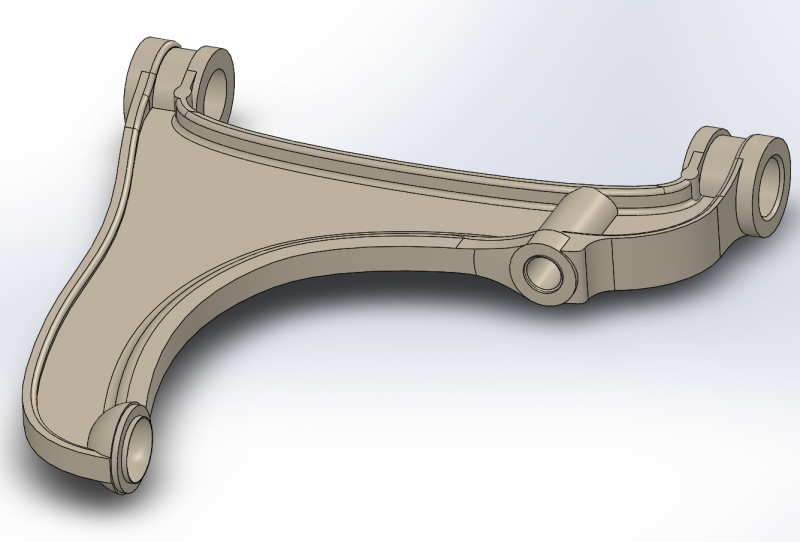

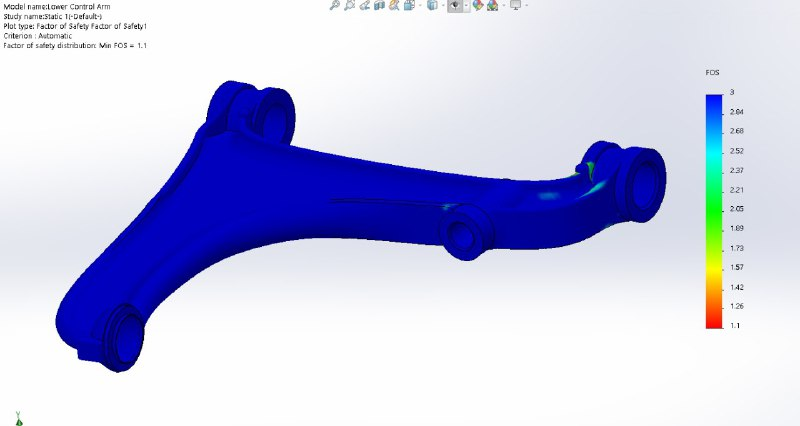

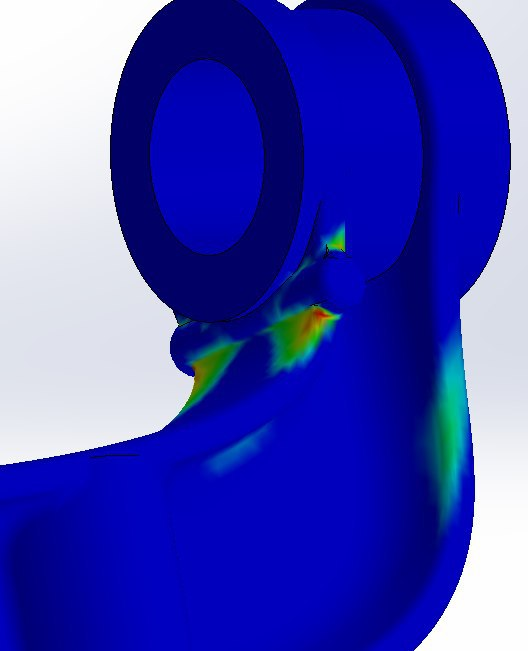

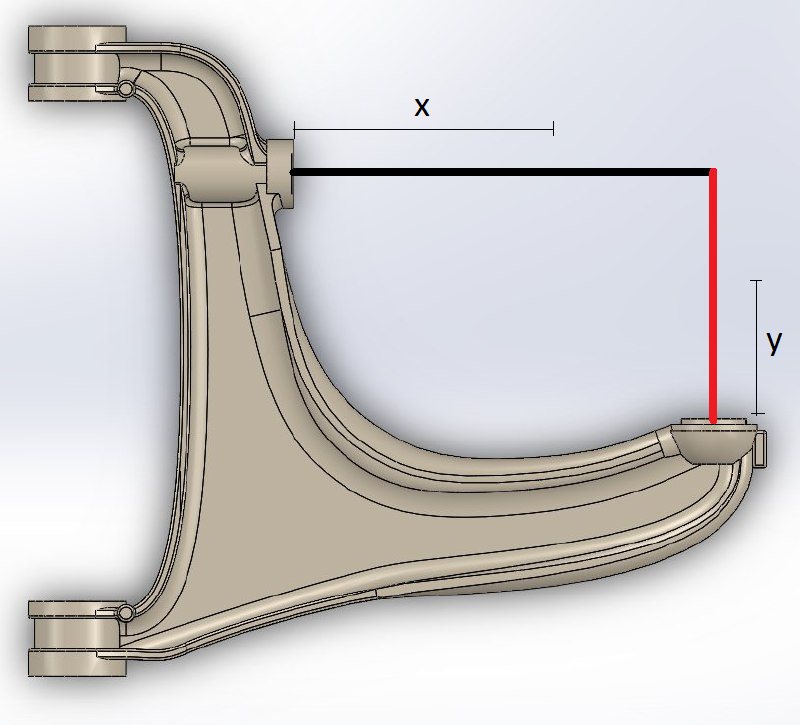

However before I do that, I'd like to understand exactly what the engineers at Fiat were doing, so I've used my report to generate an exact copy of the lower control arm. Once I have my material properties report from SGS I'll be able to simulate the part to see if there was anything specific they were trying to achieve. I'm not expecting to find anything though as it is a very simple application of double wishbone suspension.

There are some variations between the model and reality - for example I haven't included the casting line (but it is included in the model geometry, just inactive). Though I have enough information to include all the details it just simply isn't necessary or useful. The below model needs a few more details but is fundamentally correct. The round edges are a quite time consuming.