CraigWaterman11

Sponsor

- Messages

- 762

Hi guys,

I wanted to post something here, at the request of another forum member. I originally posted this in the U.S. It's something that's been talked about in a few forums around the world Maserati Life.

I kind of wanted to give a summation here because the other thread turned out to cover the entire thing but was wordy. As people talk about it I guess we can grow in it's depth. First, the people who have already experienced worn rear tie rods were shocked to find out that in order to replace them you had to buy the entire control arm. Essentially, the idea people came up with was two fold, again, in summation,

1.) Get another Spherical Plain bearing from SKF or the like, and press out the old and press another back in, (Please note the hyper-links are here for your convenience 3200/4200 Rear Suspention Toe-in Link Bearings Adam posted the link in the U.S. so I could see what you were doing here.); or

2.) Take off your OEM rear tie rod, cut the end off, get it machined for 12 mm, and screw on a Heim/Rose joint. Here is a link to check out another forum that discusses it Onderste draagarm 3200/4200

I personally didn't like either alternative. First, if you follow that hyper-link above you will find that the SKF radial, spherical plain bearing, which is the OEM bearing in the Maserati is only dynamic load rated for 18 KN or 4046.56 lbs. Not that this isn't "sufficient" but it seems to me they are failing sooner than they should be. I replaced mine at about 25,000 miles, others have lost them much sooner. In either case I just wanted another alternative to just replacing it with what was already on there, something stronger and better so I wouldn't have to replace it again.

The second option above was the hacking up of the OEM tie rod. Obviously though it will work (I think), I am definitely not a fan of cutting up OEM parts, if for no other reason, should I sell my car and someone asks for the OEM tie rods I can hand them to them without hesitation. Another part of this I was hesitant about for this option is it was manufactured for a Spherical Plain Bearing to be pressed into it. I wasn't sure of the metallurgy of the slender part of that tie rod sleeve. It obviously wasn't designed with threads on it. It might well hold, and it might not. I didn't see any testing on that site about it. It was an excellent brain storm. It might even be better than the OEM one, but I wasn't sure about the make-up.

What I set out to look for was an aftermarket replacement that completely replaced the OEM tie rod, and hardware. Since I really didn't care for the original design with the Spherical bearing because the reasons stated above. The first thing for me to look for wasn't the Rose Joint. There are many companies making Heim/Rose joints for Drag/Street/Strip racing applications as well as aircraft applications (It originated in a plane shot down by the British in World War 2). My quagmire was finding a tie rod sleeve with the correct sized threaded male ends on either side, with the correct length, and would be durable enough to handle the appropriate amount of dynamic load force. It was a quagmire because if you went to get the sleeve designed and manufactured for our applications there would be so much money involved you might as well choose one of the other choices above. No company is going to work for free.

I searched through countless hours of data for a suitable, applicable tie rod sleeve, or even something that would work close to it. I could find some with close thread size but not the appropriate length. Then the length was right but not the thread size. Some were questionable as to it's dynamic load force. Again, I want a better than OEM tie rod, not the same. Anyway, most of you who have researched this know it was a struggle. But, in the end I did find one. It was definitely already dynamic load force capable because it was originally built for a One ton truck, not for the rear of the truck, but the front where the weight sits when it's mostly emptied. Let me show you some photos of it:

The One ton truck tie rod sleeve is bigger than the OEM width at 14mm.

Now that I had a firm foundation to work from because it was designed to be a tie rod sleeve (properly threaded at both ends), and I trusted that it's dynamic load force was far beyond anything I could do in this car. I could choose a Rose Joint that would be, not sufficient, but great for this application. I stepped up to this Rose Joint that was dynamic load rated at over 11,000lbs or 48 KN! It was a self maintenance joint. ( I can add other specifications later if you'd like)

Here it is with a dust cover:

Side by side on the car:

Okay, so finally I had to make sure the off-set was correct. Now the OEM bearing only had an off-set of +/-8 degrees, this Rose joint has an off-set of +/- 15 degrees, bigger number is a good thing. That being stated, I still wanted the Rose Joint to sit exactly where the OEM bearing sat, though it really wasn't necessary:

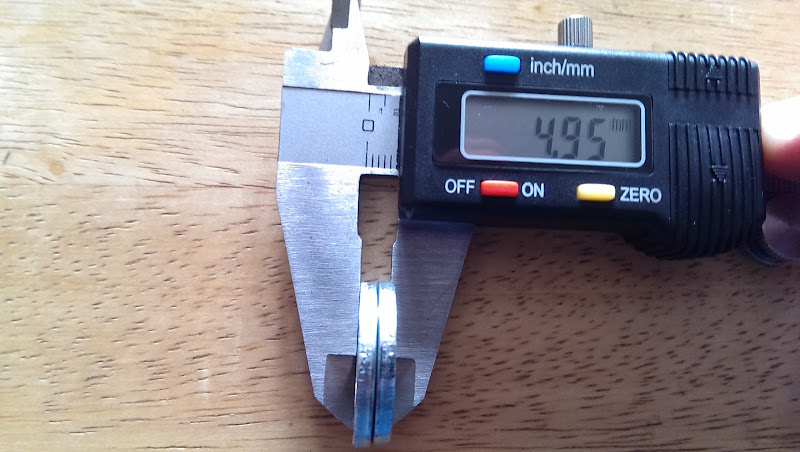

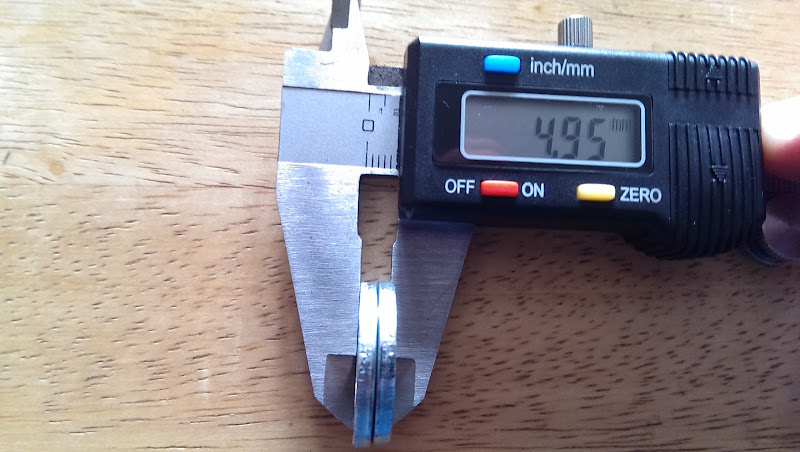

I used a digital caliper to measure the distance in front of where the OEM bearing seated, and it was this:

To make up this distance I finally settled on two Stainless Steel Washers.

Not perfect, but it was close enough to make me extremely happy.

Here's the final product:

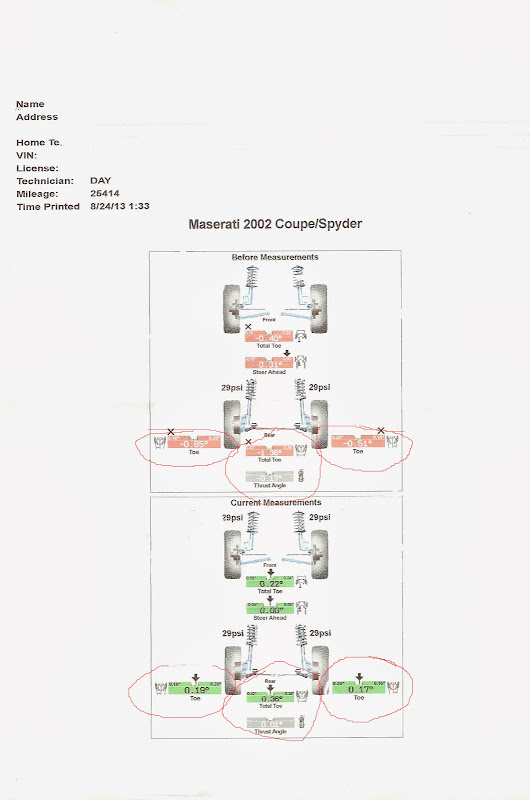

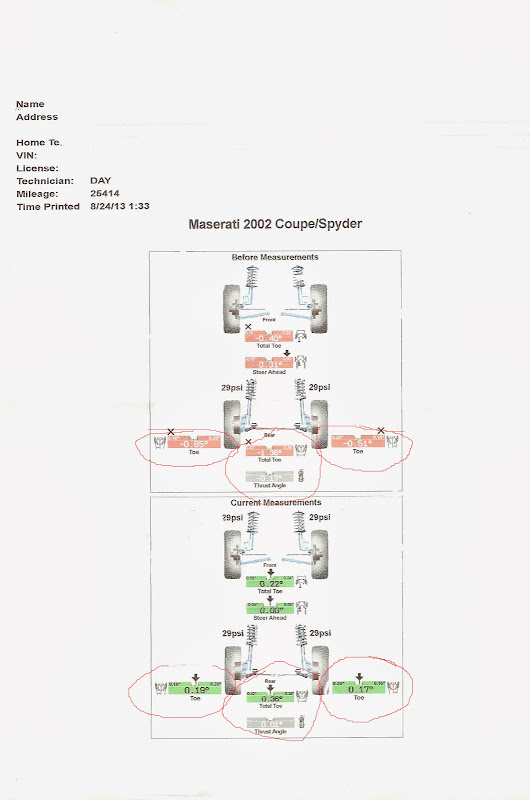

Additionally is anyone wondering where the alignment data is afterwards?

So I guess it comes down to price now. When I put all this together I wanted a price point that would be acceptable to anyone. The SKF bearing, the one hyper-linked above cost, just for the bearing I think it was $68 US dollars for one. I out-sourced the Rose Joint out of Scotland, wonderful people, great accents, that wasn't the hard part of course, neither were the washers.....The tie rod sleeves are made in North America....ironically it took longer to get these together than everything else. I bulked ordered all the parts from all these various sources, and my price point essentially to offer them was $100 US dollars per side! So total for both sides was $200, here's what the kit looks like:

Now there is a small part I left out of this, when I contacted Scotland, I asked for the biggest baddest Rose joint in the size I needed I could get. After all the research and development they email me and told me they have a "Super joint"! It's a Rose joint dynamic load rated at over 15,300 lbs or 68 KN! Since I had not mass ordered the other one, this is the Rose joint I included in the assemblies. So now the Rose joint included and is pictured below is dynamic load rated at 15,300 or 68 Kn or almost four times that of the OEM tie rod. Additionally, no cutting or machining or pressing. They fit right in place of the old ones, and they align perfectly.

With the kits I put together, I feel the forum member from here that asked me to post just felt you guys would want to know about it. I bought enough material for 14 different sets because that's what was required to receive the discount bulk order. I put 5 kit assemblies together day before yesterday, and I only have one left now. I have most of the parts, but the American company is sending small amounts at a time for whatever reason. I shipped one to Hong Kong for another forum member Express Mail International it cost about $50 but he gets it in three days with tracking. Either way, let me know if you have any questions, or contact me if your interested. I feel I did the best I could to make everything affordable and get the best bang for the buck.

I wanted to post something here, at the request of another forum member. I originally posted this in the U.S. It's something that's been talked about in a few forums around the world Maserati Life.

I kind of wanted to give a summation here because the other thread turned out to cover the entire thing but was wordy. As people talk about it I guess we can grow in it's depth. First, the people who have already experienced worn rear tie rods were shocked to find out that in order to replace them you had to buy the entire control arm. Essentially, the idea people came up with was two fold, again, in summation,

1.) Get another Spherical Plain bearing from SKF or the like, and press out the old and press another back in, (Please note the hyper-links are here for your convenience 3200/4200 Rear Suspention Toe-in Link Bearings Adam posted the link in the U.S. so I could see what you were doing here.); or

2.) Take off your OEM rear tie rod, cut the end off, get it machined for 12 mm, and screw on a Heim/Rose joint. Here is a link to check out another forum that discusses it Onderste draagarm 3200/4200

I personally didn't like either alternative. First, if you follow that hyper-link above you will find that the SKF radial, spherical plain bearing, which is the OEM bearing in the Maserati is only dynamic load rated for 18 KN or 4046.56 lbs. Not that this isn't "sufficient" but it seems to me they are failing sooner than they should be. I replaced mine at about 25,000 miles, others have lost them much sooner. In either case I just wanted another alternative to just replacing it with what was already on there, something stronger and better so I wouldn't have to replace it again.

The second option above was the hacking up of the OEM tie rod. Obviously though it will work (I think), I am definitely not a fan of cutting up OEM parts, if for no other reason, should I sell my car and someone asks for the OEM tie rods I can hand them to them without hesitation. Another part of this I was hesitant about for this option is it was manufactured for a Spherical Plain Bearing to be pressed into it. I wasn't sure of the metallurgy of the slender part of that tie rod sleeve. It obviously wasn't designed with threads on it. It might well hold, and it might not. I didn't see any testing on that site about it. It was an excellent brain storm. It might even be better than the OEM one, but I wasn't sure about the make-up.

What I set out to look for was an aftermarket replacement that completely replaced the OEM tie rod, and hardware. Since I really didn't care for the original design with the Spherical bearing because the reasons stated above. The first thing for me to look for wasn't the Rose Joint. There are many companies making Heim/Rose joints for Drag/Street/Strip racing applications as well as aircraft applications (It originated in a plane shot down by the British in World War 2). My quagmire was finding a tie rod sleeve with the correct sized threaded male ends on either side, with the correct length, and would be durable enough to handle the appropriate amount of dynamic load force. It was a quagmire because if you went to get the sleeve designed and manufactured for our applications there would be so much money involved you might as well choose one of the other choices above. No company is going to work for free.

I searched through countless hours of data for a suitable, applicable tie rod sleeve, or even something that would work close to it. I could find some with close thread size but not the appropriate length. Then the length was right but not the thread size. Some were questionable as to it's dynamic load force. Again, I want a better than OEM tie rod, not the same. Anyway, most of you who have researched this know it was a struggle. But, in the end I did find one. It was definitely already dynamic load force capable because it was originally built for a One ton truck, not for the rear of the truck, but the front where the weight sits when it's mostly emptied. Let me show you some photos of it:

The One ton truck tie rod sleeve is bigger than the OEM width at 14mm.

Now that I had a firm foundation to work from because it was designed to be a tie rod sleeve (properly threaded at both ends), and I trusted that it's dynamic load force was far beyond anything I could do in this car. I could choose a Rose Joint that would be, not sufficient, but great for this application. I stepped up to this Rose Joint that was dynamic load rated at over 11,000lbs or 48 KN! It was a self maintenance joint. ( I can add other specifications later if you'd like)

Here it is with a dust cover:

Side by side on the car:

Okay, so finally I had to make sure the off-set was correct. Now the OEM bearing only had an off-set of +/-8 degrees, this Rose joint has an off-set of +/- 15 degrees, bigger number is a good thing. That being stated, I still wanted the Rose Joint to sit exactly where the OEM bearing sat, though it really wasn't necessary:

I used a digital caliper to measure the distance in front of where the OEM bearing seated, and it was this:

To make up this distance I finally settled on two Stainless Steel Washers.

Not perfect, but it was close enough to make me extremely happy.

Here's the final product:

Additionally is anyone wondering where the alignment data is afterwards?

So I guess it comes down to price now. When I put all this together I wanted a price point that would be acceptable to anyone. The SKF bearing, the one hyper-linked above cost, just for the bearing I think it was $68 US dollars for one. I out-sourced the Rose Joint out of Scotland, wonderful people, great accents, that wasn't the hard part of course, neither were the washers.....The tie rod sleeves are made in North America....ironically it took longer to get these together than everything else. I bulked ordered all the parts from all these various sources, and my price point essentially to offer them was $100 US dollars per side! So total for both sides was $200, here's what the kit looks like:

Now there is a small part I left out of this, when I contacted Scotland, I asked for the biggest baddest Rose joint in the size I needed I could get. After all the research and development they email me and told me they have a "Super joint"! It's a Rose joint dynamic load rated at over 15,300 lbs or 68 KN! Since I had not mass ordered the other one, this is the Rose joint I included in the assemblies. So now the Rose joint included and is pictured below is dynamic load rated at 15,300 or 68 Kn or almost four times that of the OEM tie rod. Additionally, no cutting or machining or pressing. They fit right in place of the old ones, and they align perfectly.

With the kits I put together, I feel the forum member from here that asked me to post just felt you guys would want to know about it. I bought enough material for 14 different sets because that's what was required to receive the discount bulk order. I put 5 kit assemblies together day before yesterday, and I only have one left now. I have most of the parts, but the American company is sending small amounts at a time for whatever reason. I shipped one to Hong Kong for another forum member Express Mail International it cost about $50 but he gets it in three days with tracking. Either way, let me know if you have any questions, or contact me if your interested. I feel I did the best I could to make everything affordable and get the best bang for the buck.