A few posts so I thought I should follow up.

I've been a bit slack on the project the last few weeks, I've gotten quotes back so now I need to hammer out the meat of the design which is really only 2-3 days of work. What the real hold up has been is that I haven't gone bushing and ball joint hunting because that one is a 'how long is a piece of string'. I've got my car in a body shop at the moment, and while I didn't have it here distracting me I've been giving my other cars and projects some attention. Though none of it is related to this post, I thought I would let y'all know what I've been doing the last two weeks.

1- Applying for Medical School, all the applications have opened in Australia.

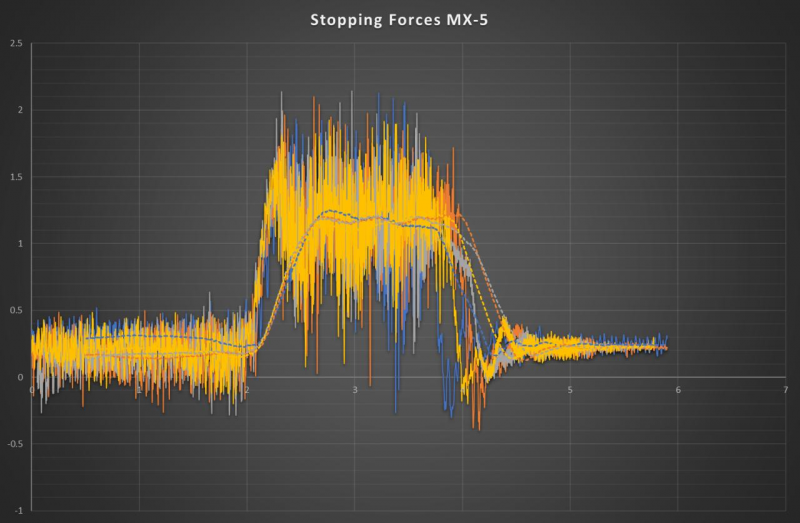

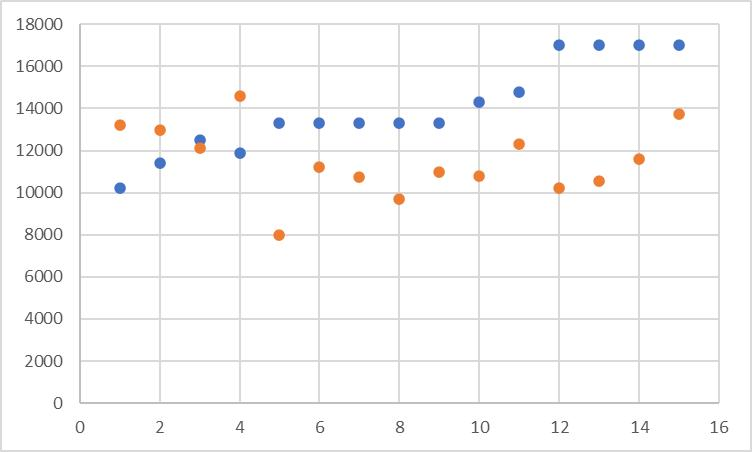

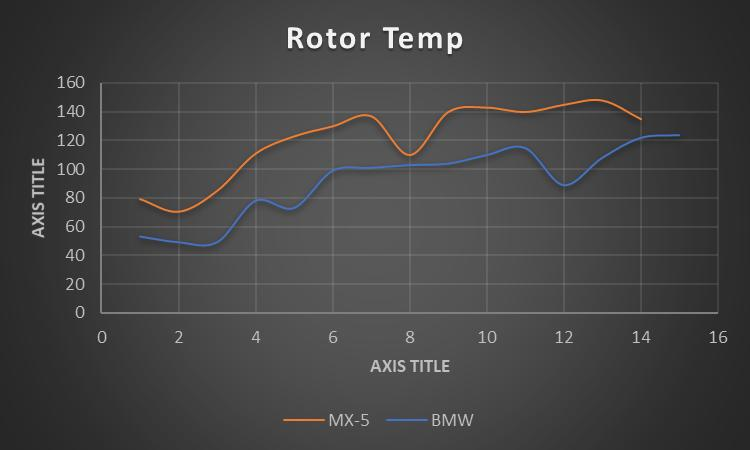

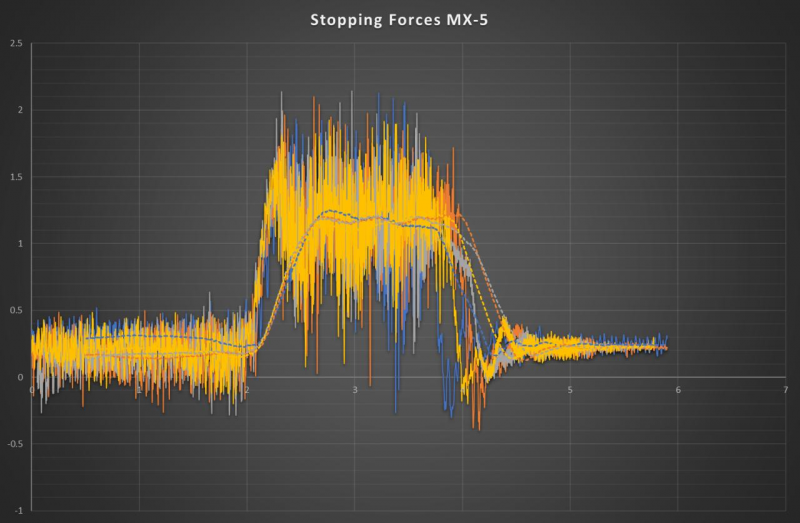

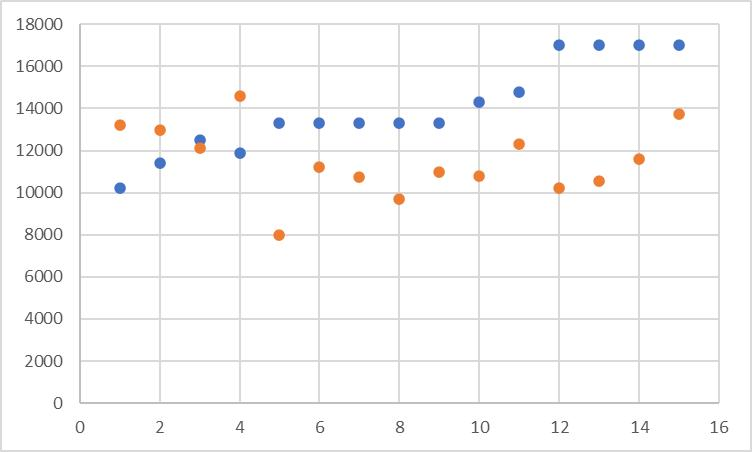

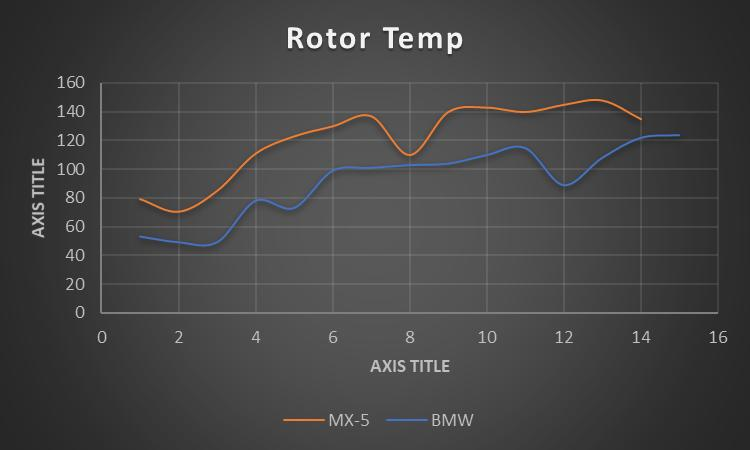

2- Characterising the way the brakes work on a couple of different cars. This is part of, but not directly related to my project of redesigning the brakes for the Maserati. Below is some raw data from my MX-5 running RE003s. Once you account for zero drift and a few other things braking forces averaged 1.2g in a 60km/hr-0km/hr test, quite impressive. I also did it on my BMW, and collected data on stopping distance, time to stop, rotor temps and everything else I need to cross-verify and validate a simplified model of rotor temps I'm making to teach people how to select brake pads. The data is raw, so don't read too much into it. All of this data is courtesy the help of my lovely fiancee.

3 - I changed the rotors on my MX-5

4 - Here is something car guys don't get to say very often - my MX-5 is a completed project! Everything is completely done! Until a rock hit the edge of the windscreen and sent a crack up the middle of the glass... Thankfully my insurance (Shannons) covers a no excess windscreen every 12 months so it is getting replaced tomorrow, which means I can finish my paint detail the day after and then go take some photos of the last car I spent two years fixing up!

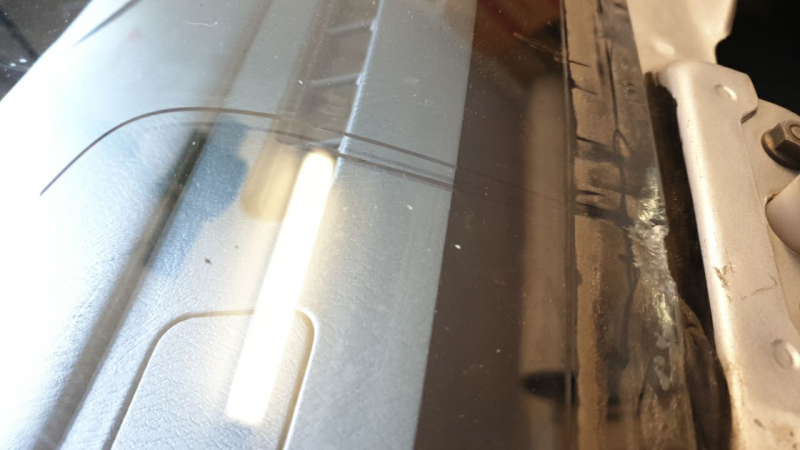

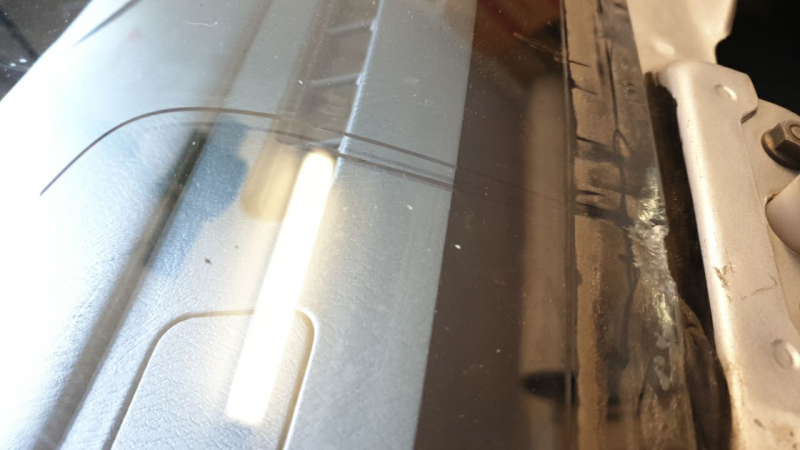

5 - Rebuilding my window reg

6 - Cleaning up my headlight lenses and getting the inserts painted.

7 - Trying to finish a flashlight project that has been running way too long... I pulled the batteries out of storage a few days ago and accidentally shorted one out. They're 20A batteries and I need two of them.

Just an update on what’s happening with my car as it’s been sitting in a workshop for a few weeks now; mainly waiting for parts. Control arms were one issue and a problem engaging reverse the other. Replacing the gear lever with a Hills version only part fixed the latter problem as It turns out the power unit is playing up as well. I’ve sourced a 2nd hand replacement and all work should be done this coming week (including fitting a FD DBW conversion) - fingers crossed the car will then drive and behave like it should

Fingers crossed it drives and behaves not line mine! I've got some good spares from all my transmission hullabaloo, so if you still need parts send me a PM. Not all of it is trashed.

Great initiative and awesome work by

lambertius! Im rooting for you and hope you'll come up with a great build on these control arms!

Im driving a 2010 Granturismo 4.7L F1. Would love to see you design one for GT/Quattroporte as well!

Also, this might be silly but I came across this websit that rebuilds Lambo control arms

https://gallardocontrolarms.com/. Seems like a similar problem to our Maseratis' ball joints, is it?

There is an old thread on here where someone was trying to come up with a similar solution for our arms, I ended up PMing them before taking this on to work out why they never completed it. He was held up with costs, and the arrangement of our arms isn't quite as convenient as the Gallardo to be reworked. So the issue is present across the next generation as well? If I can pull this off successfully, and someone can source me scrap parts for measurement I'd be happy to take it on. Obviously a bit of time before I get to that as this is still ongoing, but yeah - if someone finds the parts at any point send them my way!