Did not have a lot of additional garage time so far, there quite a lot of work so far, but there is promising progress finally.

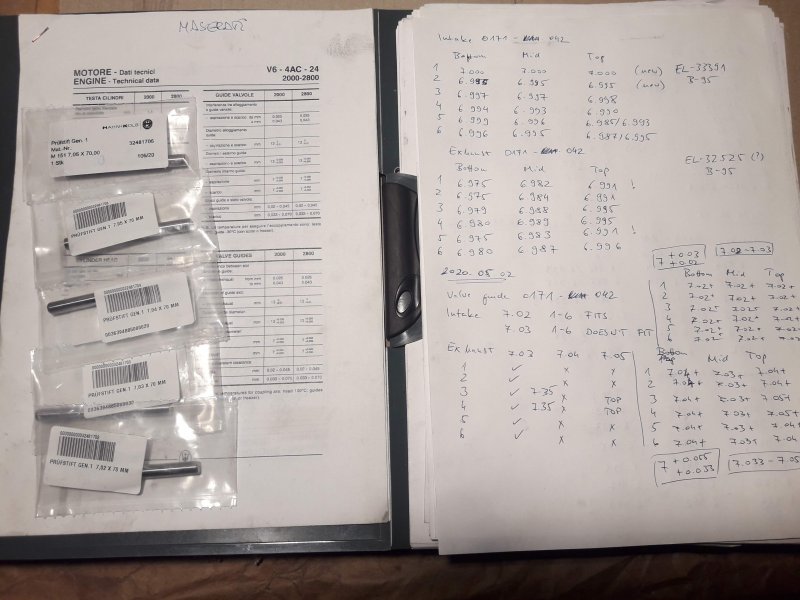

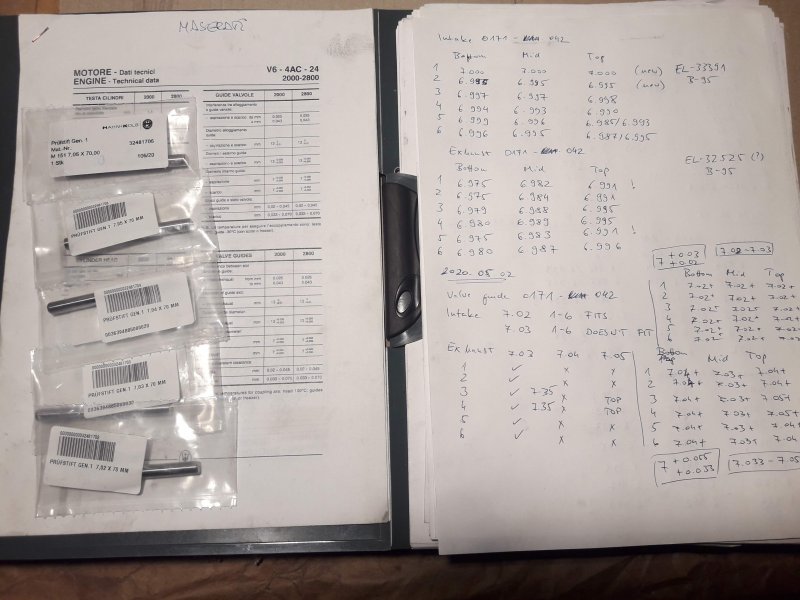

I really wasn't satisfied with that cam bearing repair last time. Finally found a workshop who did what I've asked for, cam clearances and bearing surface is now perfect. Also spent a lot of time measuring everything, all the clearances: cams, tappets, valve / guides.

For lightly cleaning up the surfaces got a precision ground steel plate, and used emery plate on top, just as described in the workshop manual. Since I had the old heads, first practiced on those, and got better flatness than that first amateur machine shop did. Did start with 120 grit, higher values required a lot of work to remove material. Stopped at 220 which should be around 50 Ra. Those peaks and valleys were gone. Btw, I'm still planning to fix up those heads in the future, maybe put new seats and slightly bigger valves in them just for experimentation.

After that came the CC volume. Made one side pretty much identical (in measurement error, which is around 0.1cm3), but took nearly a day, so gave up on the other side, but all of them are in 0.5cm3 difference.

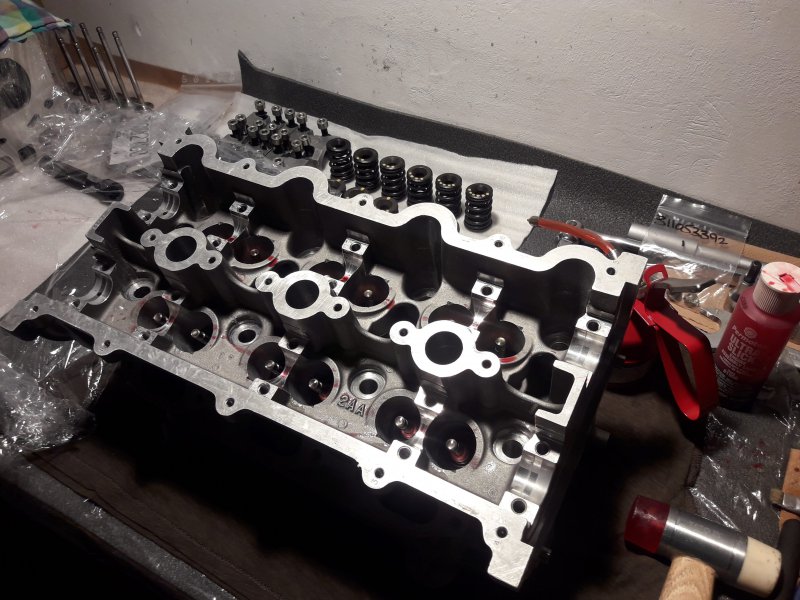

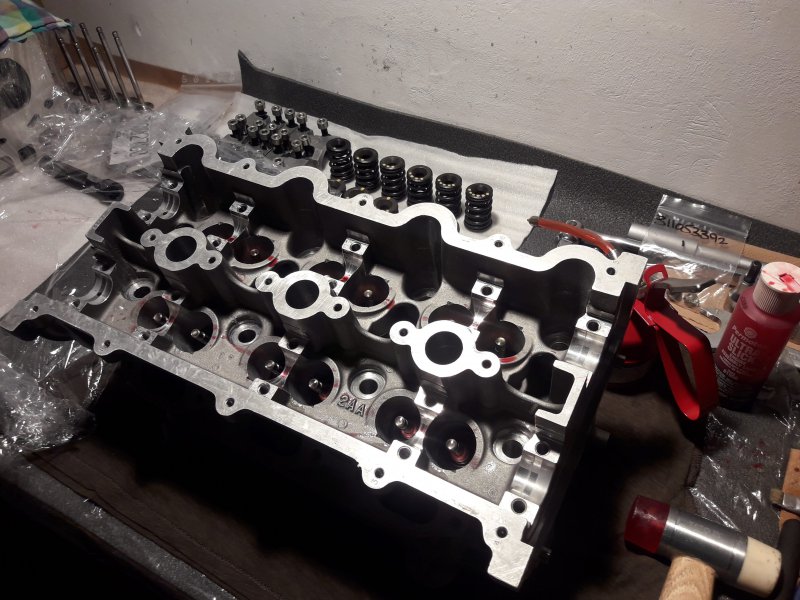

Valves reinstalled, set up the initial clearances. This should be on the loose side before assembly, as they tighten up when torquing down the heads.

On the weekend the heads were installed, filled up the coolant passages after plugging all the hoses and did a leak down test. No bubbles! Also did pressurized the coolant side, and checked the cylinders. No leaks! On one side I've reused the custom head gasket which I've tried last time (engine wasn't started), but I wouldn't have slept well with that in, especially since the old head left those surface marks on the fire rings.

Today received a new gasket which I'm going to install in the coming days. Then what's left is setting up the timing and the engine can go back in the car.