spacecadet

Member

- Messages

- 378

Hi,

I'm soon starting this winter's work, will share progress here.

The planned items, it's a pretty long list, hope will finish before the season:

I'm soon starting this winter's work, will share progress here.

The planned items, it's a pretty long list, hope will finish before the season:

- Pull engine and gearbox - DONE

- Fix and strengthen cracked R.H. chassis rail, while there also tackle a small rust spot below one of the air filter and also at two corners near the front shocks in the wheel well (will be done by a workshop doing bodywork and rollcages for race cars) - DONE

- Replace timing chains (current state: ), set timing and valve clearances - DONE

- Replace leaking crankshaft seal, while there also replace camshaft seals - DONE

- Repaint flaking intake manifold and valve covers - DONE

- Send leaking AC compressor for overhaul - DONE

- Replace disintegrated hood foam

- Overhaul front suspension; media blast, paint, replace rubber parts, joints, etc. like last winter the rear - DONE

- Send shocks to be tested / overhauled; nothing wrong with it but since the whole suspension will be done I thought let's do this too now - DONE

- Install Cup springs - DONE

- Install K.S. ARBs; still have to find rubber mounts for these, especially for the rear - DONE

- Resurface flywheel - DONE

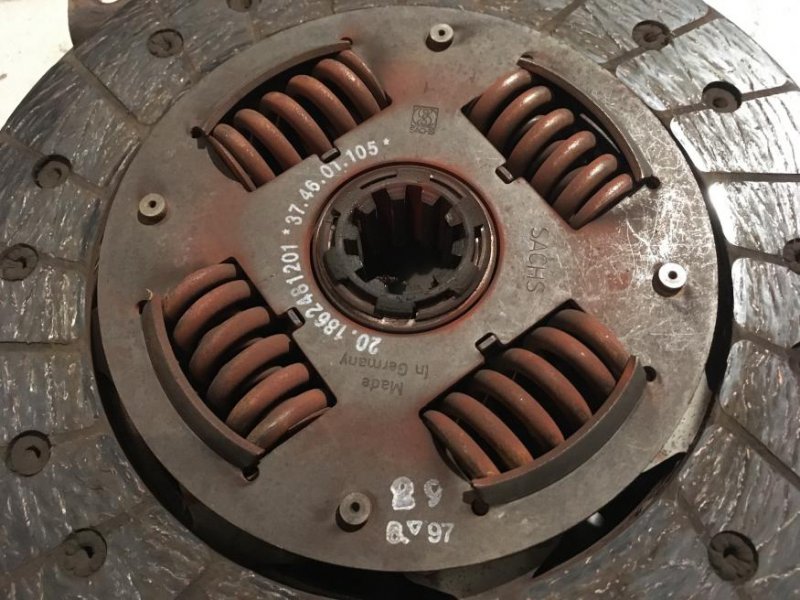

- Replace clutch, pressure plate, release bearing and pilot bearing; the clutch is very heavy, only bites at the top, the bearing is really noisy - DONE

- Install fully revisioned spare gearbox - DONE

- For pulling the engine with the gearbox, should I remove the front tubular structure or can this be done by simply lifting them upwards?

- How can I fix the camshafts to remove and later fix the front timing pulley and also the rear nuts holding the gears?

- Should I clean the oil galleys inside the camshafts too as described in the manual or not necessary?

- Are thickness pads still available from Maserati? I have to wait with the order until the current ones are accessible.

- Do I need a special tool for replacing the crankshaft seal and the input shaft bearing?

- Is it advised to skim the flywheel when installing a new clutch? If yes, what's the factory limit? Didn't find anything in the manual.

- Anything else I should be aware of? I've only done a head job before so not so much experience working on engines, but I have time and patience

Last edited: