You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear boxes on the inside

- Thread starter maverick

- Start date

Spartacus

Member

- Messages

- 3,188

You have to remember as a manufacturer there are EU rules on noise emission, you can't just chuck on some aftermaket stuff, it all has to be homologated and have E number cert

And they tuned the engines of the day to suite there exhausts!

Dave

Luckily I'm not a manufacturer , so I'm getting my grinder and large hammer out if my tool box ;p

..... And some ear defenders !

maverick

Member

- Messages

- 1,982

Just ordered two large 2.5" bends , cost £38 inc . Sparticus I used a grinder with a 2mm disc to slice open the cans and a grinding disc to grind the weld joint quite simple and quick to do , cutting the pipes out might be a pig , iam going to use a recipitating saw .

maverick

Member

- Messages

- 1,982

Spartacus

Member

- Messages

- 3,188

cutting stainless is a pig . you really need to do it in a machine shop with a cutting blade on a grinder or have it cut with a torch . i may draw up some plans for my attempt . i may go with square internal tube to make the jointing easier ! why make thing difficult ! ;P

maverick

Member

- Messages

- 1,982

Spartacus

Member

- Messages

- 3,188

highlander

Member

- Messages

- 5,236

That's handy than

View attachment 26537

A great photo for a game of I-spy........can anyone see the block of Parmesan?

Spartacus

Member

- Messages

- 3,188

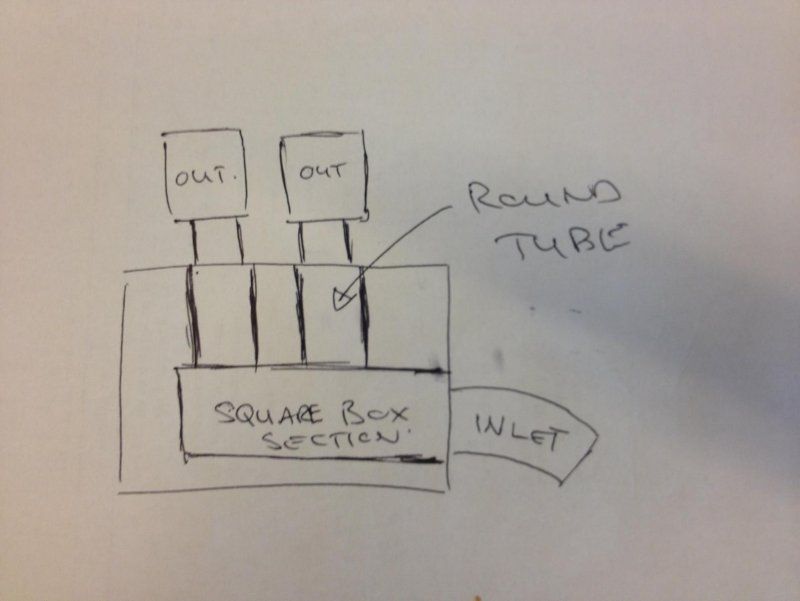

Yep I wasn't exspecting that to makes life a bit more difficult but this is what I was thinking .

It's roughly to sale , need a reducer , a bend and some pipe .

View attachment 26534

Im going to go with this because if you use square section in welded to flat cut tubes you dont have to scollop the tubes .

Spartacus

Member

- Messages

- 3,188

^^^Thats how the GS boxes are done albeit with drilled pipe on the quiet side.

You could save yourselves alot of aggro and do it with flexi pipe and a 2 into 1 collector

View attachment 26541

View attachment 26542

Good idea , but i think it would be more agro trying to weld that flexi to the housing maybe ?

maverick

Member

- Messages

- 1,982

On to stage two , remove all the internals

View attachment 26546

View attachment 26546

Spartacus

Member

- Messages

- 3,188

On to stage two , remove all the internals

View attachment 26546

Can you re post your picture . I can't seem to see it ? Or is I just my phone ?