boomerang

Member

- Messages

- 412

Even when a car does not run for a few years, suspension parts deteriorate due to oxidation.

Time to act.

Bought a sandblasting cabinet and got working.

First and most important problem was rust at the outer ends of both springs.

After sandblasting and powder coating the springs, they got crimp sleeves at the outer ends, where the first windings touch each other.

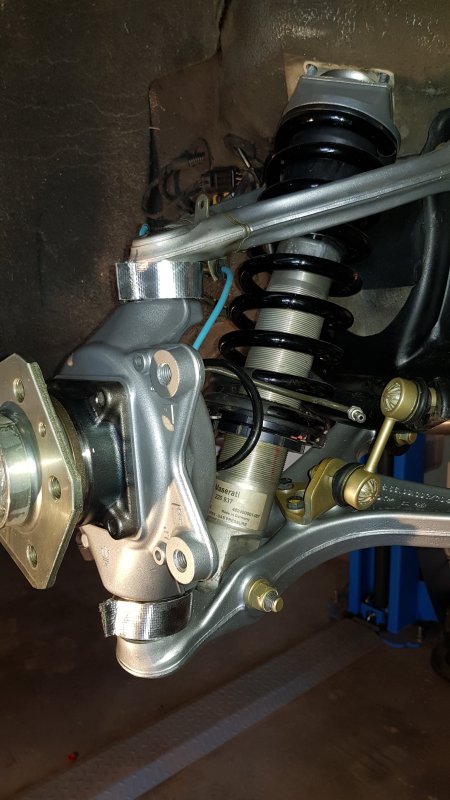

Then the wishbones and hubs where done; pearl blasting, 2k clear coat.

Happy to see that there where no cracks, was no rust or oxidation at the fanblock housings.

Looks quite nice, doesn’t it?

Time to act.

Bought a sandblasting cabinet and got working.

First and most important problem was rust at the outer ends of both springs.

After sandblasting and powder coating the springs, they got crimp sleeves at the outer ends, where the first windings touch each other.

Then the wishbones and hubs where done; pearl blasting, 2k clear coat.

Happy to see that there where no cracks, was no rust or oxidation at the fanblock housings.

Looks quite nice, doesn’t it?