conaero

Forum Owner

- Messages

- 34,656

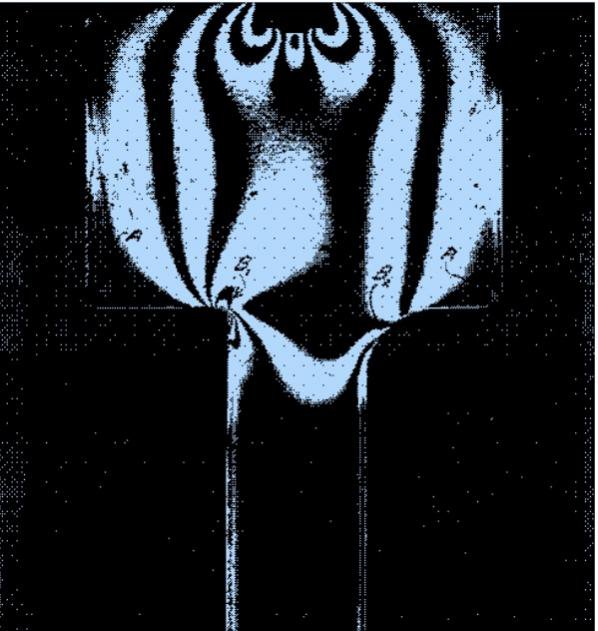

Ok just done a thorough inspection of the above arms and I am please to report that there are zero signs of metal fatigue:

The crack appears from the inside to the outside of the bolt hole then along the casting flange to the other end of the bolt hole.

My feeling is that Marios is correct that the improper replacement of the fanblocks or seized bolts stresses the area and it splits down the casting.

I am not convinced of Marios's technique is not without pending incident also but I would give it a go but have regular inspections for the first few K's miles

The crack appears from the inside to the outside of the bolt hole then along the casting flange to the other end of the bolt hole.

My feeling is that Marios is correct that the improper replacement of the fanblocks or seized bolts stresses the area and it splits down the casting.

I am not convinced of Marios's technique is not without pending incident also but I would give it a go but have regular inspections for the first few K's miles