Looking again at the pictures I must admit ABF heads are not identical. Now I wonder if VW are Coscast, I see VW stamps. A year ago I spent so much time studying posts and pictures that I probably convinced myself. My goal was to find the same kind of chambers to know how much horses they can potentially produce.

However there are striking similarities with the VW heads in details that are uncommon on car engines.

The 2v heads can't be compared with 4v ones because they can't have central spark plugs. That's an important detail about the combustion and maximum effective compression.

Sorry A.S. Motorsport I could not find any Lambo or Ferrari 4v head with the same head architecture.

TC heads are a very traditional hemi design except for separated intake ports.

There was a post on a VW forum (can't find it) where there was an excerpt from a book explaining the VW intake valve is set at the 24 degrees angle. This is about what I found on the Mase 24v heads.

I'm copying this picture of a cutaway, couldn't insert a link, sorry. Comes from :

https://clubgti.com/forums/index.ph...and-maximum-porting-dimensions-thread.193826/

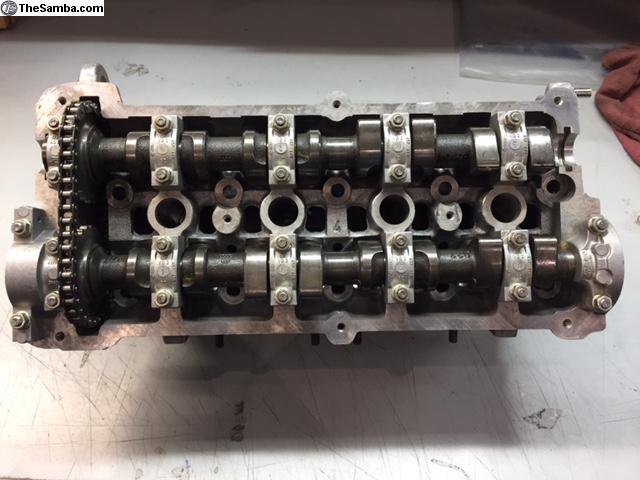

Few other pictures from the web:

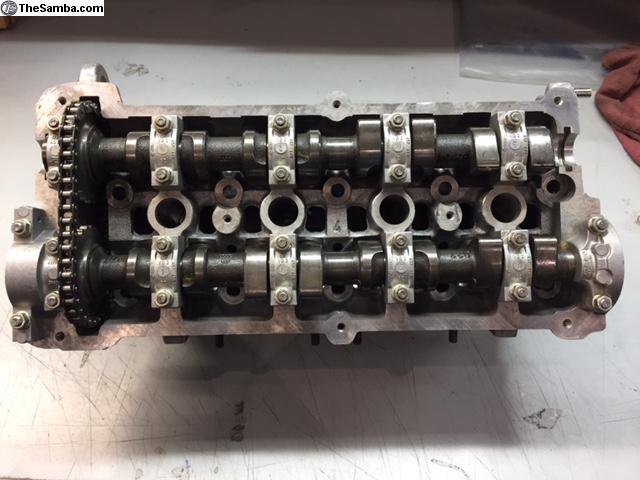

Now compare with Maserati v6 24v head:

On this picture the chain is missing, it'd be on the left side of the cams.

Of course for every time period there are dominant ideas. So it's not surprising to find similar concepts on many engines. For example the v6 18v cambox oiling is about the same as on the Porsche 944 head, the crank case looks similar to the Porsche 928, and many other.

But the 24v head is really special, that's my point. It goes against the main idea of hemispheric heads that are supposed to create compact almost symetrical chambers with one central spark plug and the biggest possible valves that would not be shrouded inside the head. The valve inclination should decrease the amount of turns in the ports and optimize the flow to and from the cylinders.

However there are striking similarities with the VW heads in details that are uncommon on car engines.

The 2v heads can't be compared with 4v ones because they can't have central spark plugs. That's an important detail about the combustion and maximum effective compression.

Sorry A.S. Motorsport I could not find any Lambo or Ferrari 4v head with the same head architecture.

TC heads are a very traditional hemi design except for separated intake ports.

There was a post on a VW forum (can't find it) where there was an excerpt from a book explaining the VW intake valve is set at the 24 degrees angle. This is about what I found on the Mase 24v heads.

I'm copying this picture of a cutaway, couldn't insert a link, sorry. Comes from :

https://clubgti.com/forums/index.ph...and-maximum-porting-dimensions-thread.193826/

Few other pictures from the web:

Now compare with Maserati v6 24v head:

On this picture the chain is missing, it'd be on the left side of the cams.

Of course for every time period there are dominant ideas. So it's not surprising to find similar concepts on many engines. For example the v6 18v cambox oiling is about the same as on the Porsche 944 head, the crank case looks similar to the Porsche 928, and many other.

But the 24v head is really special, that's my point. It goes against the main idea of hemispheric heads that are supposed to create compact almost symetrical chambers with one central spark plug and the biggest possible valves that would not be shrouded inside the head. The valve inclination should decrease the amount of turns in the ports and optimize the flow to and from the cylinders.

Last edited: