Has anyone tried removing the damper pulley from their 4200...?

Ive read of a special tool, and I realise I could probably lock the flywheel with a bar if I had two pairs of hands...!

Perhaps there is enough compression to get the screw undone if I leave it in gear...?

It isnt a QP...so when others have been able to get an impact in there to undo it..I seriously doubt this will work on a 4200...

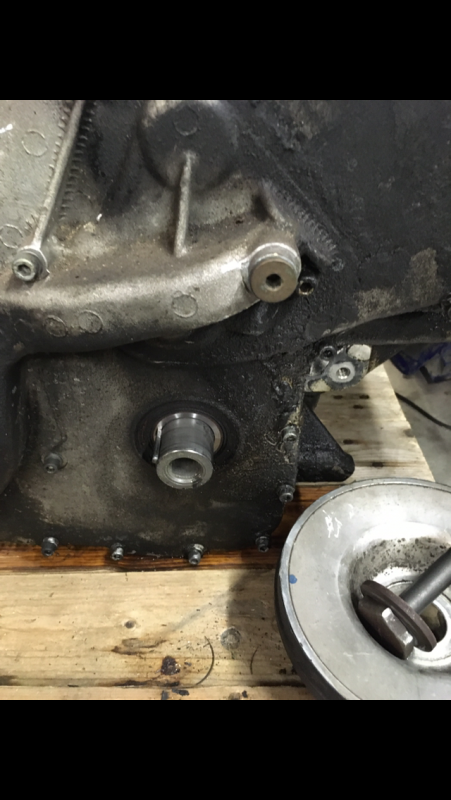

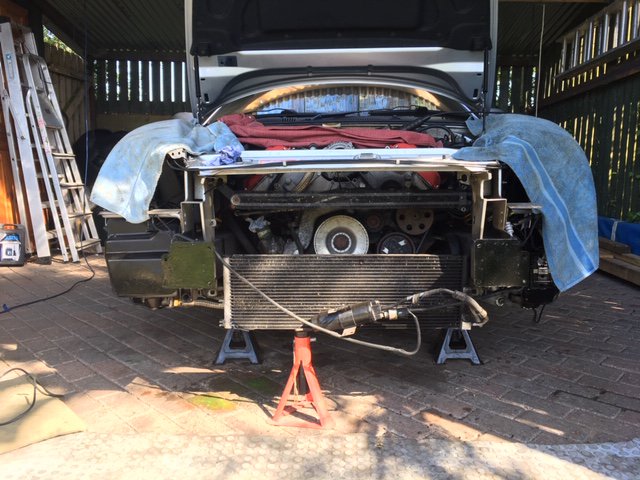

Im looking at removing the crankcase front cover to stem a water ( and oil) leak. I could consider removing the radiators as this could make life much easier all round but with aircon gases an 'all, Im not up for this at home....

cheers.

Ive read of a special tool, and I realise I could probably lock the flywheel with a bar if I had two pairs of hands...!

Perhaps there is enough compression to get the screw undone if I leave it in gear...?

It isnt a QP...so when others have been able to get an impact in there to undo it..I seriously doubt this will work on a 4200...

Im looking at removing the crankcase front cover to stem a water ( and oil) leak. I could consider removing the radiators as this could make life much easier all round but with aircon gases an 'all, Im not up for this at home....

cheers.