Ewan

Member

- Messages

- 6,818

Definitely talk to Myles at Emblem. He is currently rebuilding an engine after end float issues so is bang up to date with what parts are not available. It's taken about three months to source the bits, many of which are only available from the specialist used market (so have to go off to be checked and remachined before re-use).

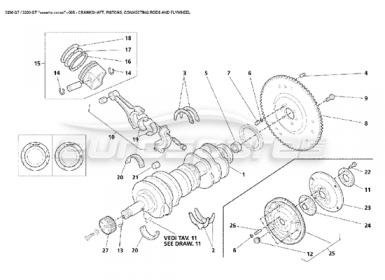

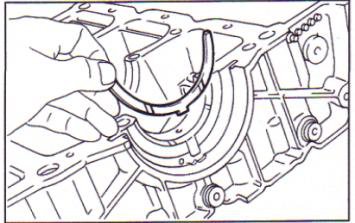

This particular car was a low mileage, full history example that was driving perfectly well when the end-float measurement was deemed worrying. When the engine was taken out and stripped, the crankshaft was worn and distorted, the bottom end damaged, the heads were worn and corroded, etc. So the rebuild is bigger and more expensive than you might think. Probably in the region of £15k - approximately the value of the car. The plan is to have it completed by late summer, at which point it will be an excellent example of a 3200 GT with a fully rebuilt engine.

This particular car was a low mileage, full history example that was driving perfectly well when the end-float measurement was deemed worrying. When the engine was taken out and stripped, the crankshaft was worn and distorted, the bottom end damaged, the heads were worn and corroded, etc. So the rebuild is bigger and more expensive than you might think. Probably in the region of £15k - approximately the value of the car. The plan is to have it completed by late summer, at which point it will be an excellent example of a 3200 GT with a fully rebuilt engine.