You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Warning!

- Thread starter mchristyuk

- Start date

mchristyuk

Junior Member

- Messages

- 668

It's pretty grim looking at those pictures..

Just be glad they're in your hands and cracked, not spread across the road like mine were...!

Mark

Just be glad they're in your hands and cracked, not spread across the road like mine were...!

Mark

mjheathcote

Centenary Club

- Messages

- 9,046

Just a thought here guys....of all the pics shown, the bushes all look in poor condition...

Maybe when the metal outer part of the bush starts to corrode it expands and eventually cracks the aluminium mounting...

Just a thought

Dave

Looking at the pictures of failed wishbones, you may have a point...

Zep

Moderator

- Messages

- 9,336

Zep

Drop link is off.

One top hat bush is out. Think the other has been fitted incorrectly from the inside. Might need to bash it across.

Sent from my iPad using Tapatalk

Ah, someone has been there before you!

Sent from my iPhone using Tapatalk

Zep

Moderator

- Messages

- 9,336

I did change them, but it is a bit of a pain. First I tried to use a 10 tonne press to remove the bushes with a custom tool to fit just around the outer lip of the bush. It maxed out the press without moving at all, although I understand others have managed to remove them this way.

When that failed I had to resort to the delicate and brutal method which was cutting out the centre of the bush, removing the rubber, weakening the outer shell with a hacksaw and dremel and then using my vice to collapse the outer lip enough to allow it to be pressed out. Pressing in the new bush was a bit easier then removal. I heated the arm, put the bushes in the freezer and used some high pressure lube and even then they were a very tight interference fit. Now I've done 8 of them I have the technique sussed so I will do some pictures when I do the rears. Obviously this method is probably only for those with experience of doing this sort of thing before on something a bit less expensive.

I used OEM bushes from Eurospares as the chap with the press has had issues with the Superformance versions on some Ferrari cars. They can have a short working life apparently.

When that failed I had to resort to the delicate and brutal method which was cutting out the centre of the bush, removing the rubber, weakening the outer shell with a hacksaw and dremel and then using my vice to collapse the outer lip enough to allow it to be pressed out. Pressing in the new bush was a bit easier then removal. I heated the arm, put the bushes in the freezer and used some high pressure lube and even then they were a very tight interference fit. Now I've done 8 of them I have the technique sussed so I will do some pictures when I do the rears. Obviously this method is probably only for those with experience of doing this sort of thing before on something a bit less expensive.

I used OEM bushes from Eurospares as the chap with the press has had issues with the Superformance versions on some Ferrari cars. They can have a short working life apparently.

Rex B

Member

- Messages

- 657

So how many cars are off the road now?

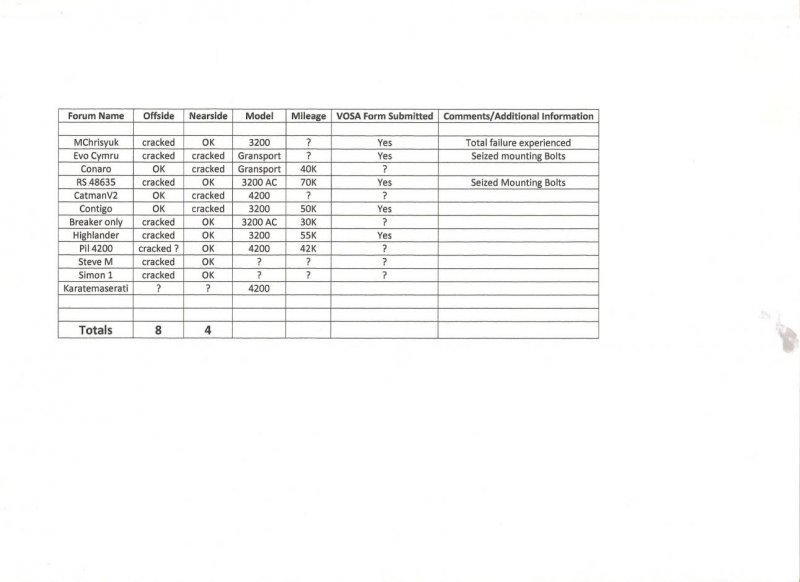

I got bored this morning and so I skipped quickly through the thread and then put together the table below listing those who have reported cracked wishbones. Where there is missing information or if any item is incorrect if members PM me or update me via the thread I will update the table.

Forum Name Offside Nearside Model Mileage VOSA Form Submitted

MChrisyuk cracked OK 3200 ? Yes

Evo Cymru cracked cracked Gransport ? Yes

Conaro OK cracked Gransport 40K ?

RS 48635 cracked OK 3200 AC ? Yes

CatmanV2 OK cracked 4200 ? ?

Contigo OK cracked 3200 50K Yes

Breakeronly cracked OK 3200 AC 30K ?

Highlander cracked OK 3200 55K Yes

Pil 4200 cracked ? OK 4200 42K ?

Steve M cracked OK ? ? ?

Simon 1 cracked OK ? ? ?

Karatemaserati ? ? 4200 ? ?

Totals 8 4

Rex B

2b1ask1

Special case

- Messages

- 20,312

Zep,That sounds like a huge amount of pressure to put on to what is an old aluminium thin wall casting, no wander they suffer from metal fatique!

Dave

I agree it seems an extreme amount of pressure but the resultant cracks are not in the thinnest part as you would expect from a pressure failure, these are ALL within the thicker mould seam area and I seriously suggest this is formed by contamination at the leading edge when the two parts of molten flow meet as it spills over the top of the bush void, just a small amount of slag or debris from the mould or cooling metal at the end of the run would be enough of an inclusion to set up this failure. There is just too much consistency proven, a pressure failure would be more jagged and in random locations near to the thinnest sections.

Zep

Moderator

- Messages

- 9,336

Zep,That sounds like a huge amount of pressure to put on to what is an old aluminium thin wall casting, no wander they suffer from metal fatique!

Dave

I'm pretty comfortable with it. The elasticity modulus for high strength aluminium is in the high tens of thousands mPa, significantly higher than the pressure I can manage with workshop tools. Fatigue I understand to be caused by regular small elastic deformation (i.e in use) so my efforts are unlikely to worsen this situation. More of a concern would be surface damage by tooling and incorrect mounting of parts in the press and this was what pushed me down the route of a more gentle removal. My research prior to this indicated that the same bush in the Ferrari 550 (I couldn't find any evidence of failures in the 550) takes up to 7 tonnes before they come out of the arms. They are clearly a very tight fit intentionally.

We have got several different theories as to the cause of the failures and most likely the outcome will be a mixture of a few of them. For my pennies worth, having seen the beginnings of rust on the internal bearing surfaces of my lower bushes I think that a partial seizure of the bush inner sleeve causes the rotational movement to be transferred to the outer part of the bush and this means the bush tries to rotate in the arm. This rotational movement puts a tensile stress on the outer part of the arm and it fails at the weakest point - As Newton says, there is more likely to be porosity where the material flowed into the mould.

Having said all of that, I await with interest the results of any metallurgical testing of failed components and the dissection of a bush from a failed part. This would be extremely informative in my view, at which point I reserve the right to change my mind!