Klive

Junior Member

- Messages

- 724

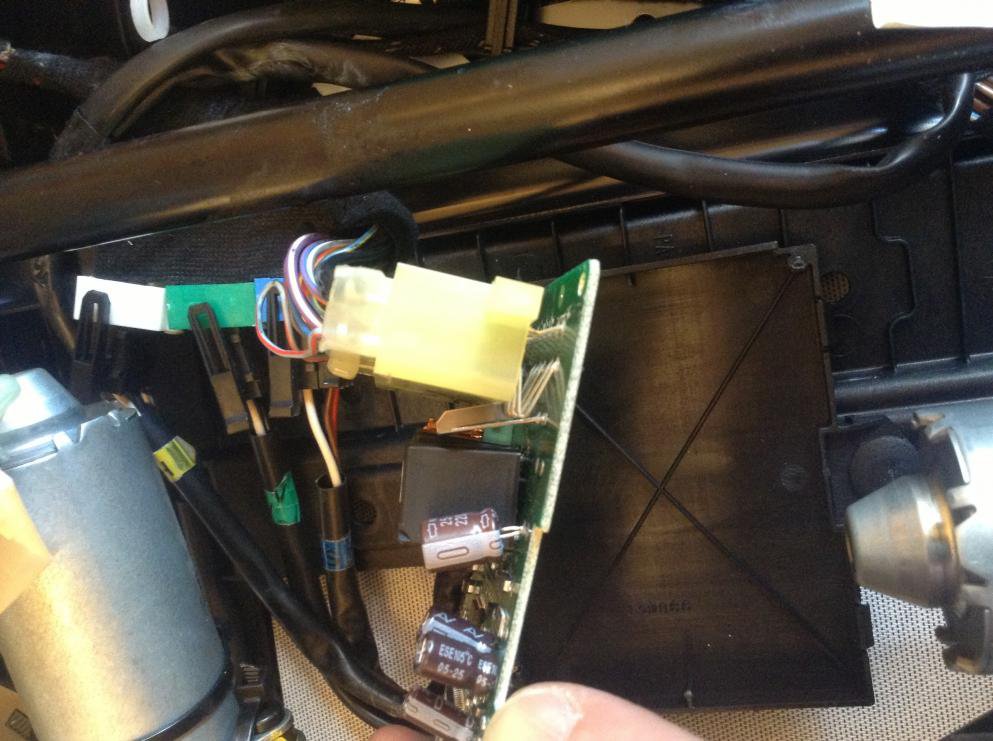

Quite fortunate that they did as when I looked under the passenger seat I saw a PCB that I thought was fixed to the floor. The box that secured it to the bottom of the seat had fallen off and the board had wedged itself between the seat and carpet during one of its movements.

I disconnected and reconnected the connector and the seat sprang back into life again. Lifting the seat gave me access to work on it to put it all back up again.

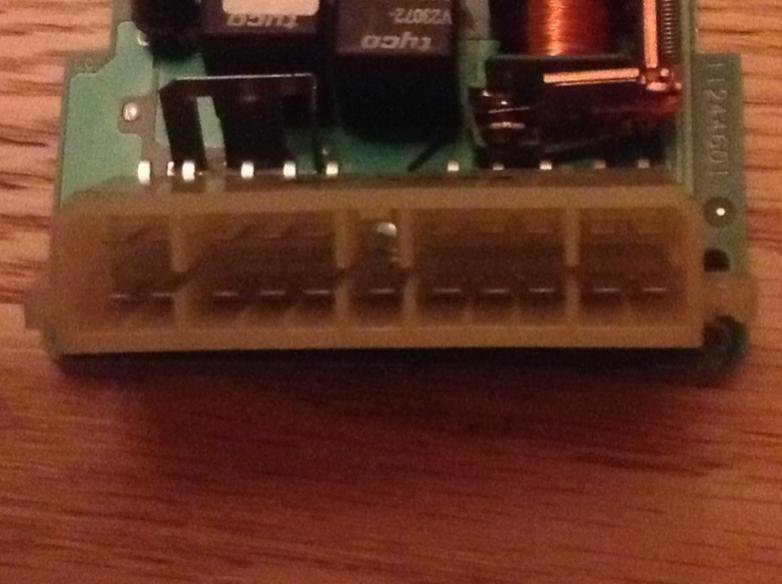

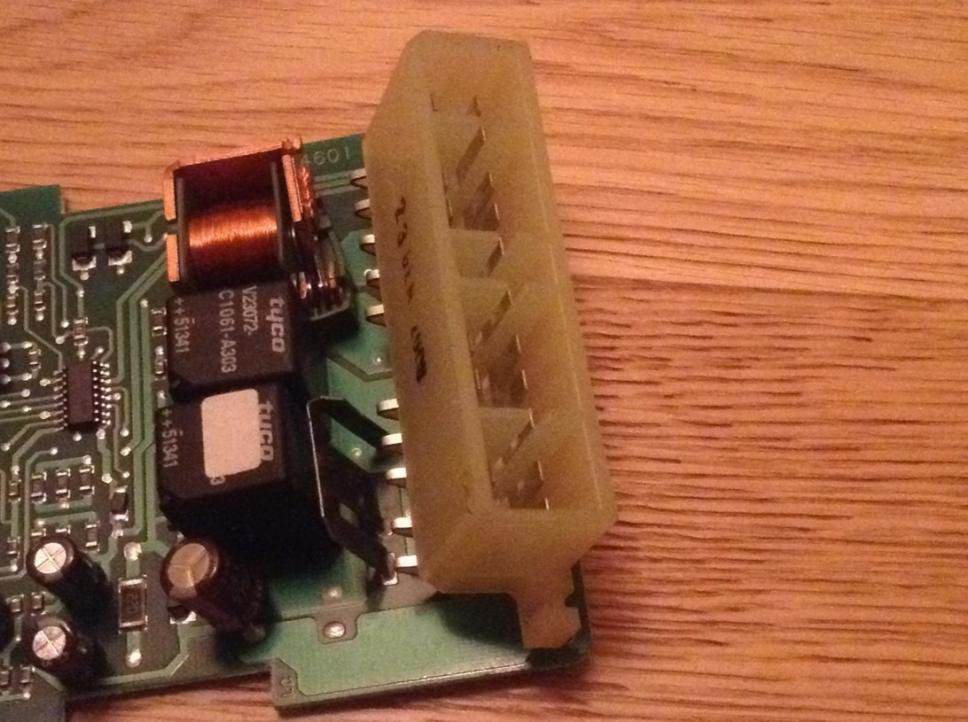

The board has bent slightly but is substantial enough to take it. Here's a couple of photos that I took with the phone.

I disconnected and reconnected the connector and the seat sprang back into life again. Lifting the seat gave me access to work on it to put it all back up again.

The board has bent slightly but is substantial enough to take it. Here's a couple of photos that I took with the phone.