B16 ONX

Junior Member

- Messages

- 95

Hey guys

So since I bought my QP back in March it has never been "right". The power delivery wasn't as smooth as I expected, the clutch control was terrible when it was cold, the throttle had very little connection with the engine when it was cold & it wouldn't rev past 5500 rpm. When it was hot it was better, but only better not right. It felt like it was down on power, not by much but didn't have that "vigour" I was expecting.

As this was my first QP V I reluctantly put it down to being how it was supposed to be.....but then common sense kicked in & there is no way Maserati would release a car with these characteristics.

I took it to Vince@ Migliore Cars for him to give it a once over & he agreed with the lack of revs but felt all else was ok.

He carried out a free diagnostic check which found that the knock sensor was faulty. He cleared the fault & we left it at that. Last month I had enough so I contacted him again so he could get to the bottom of the fault as it was no longer any fun.

Unfortunately he was going away on holiday the following week & would be busy before & after his holiday so I reluctantly booked it in at Graypaul in Solihull.

They had it for a couple of days & they came back with the same diagnosis, the knock sensor was faulty. I asked how much to remove & replace & was quoted £1478 for parts & labour!

I brought the car back whilst I pondered what to do. I decided to do the job myself, how hard could it be?

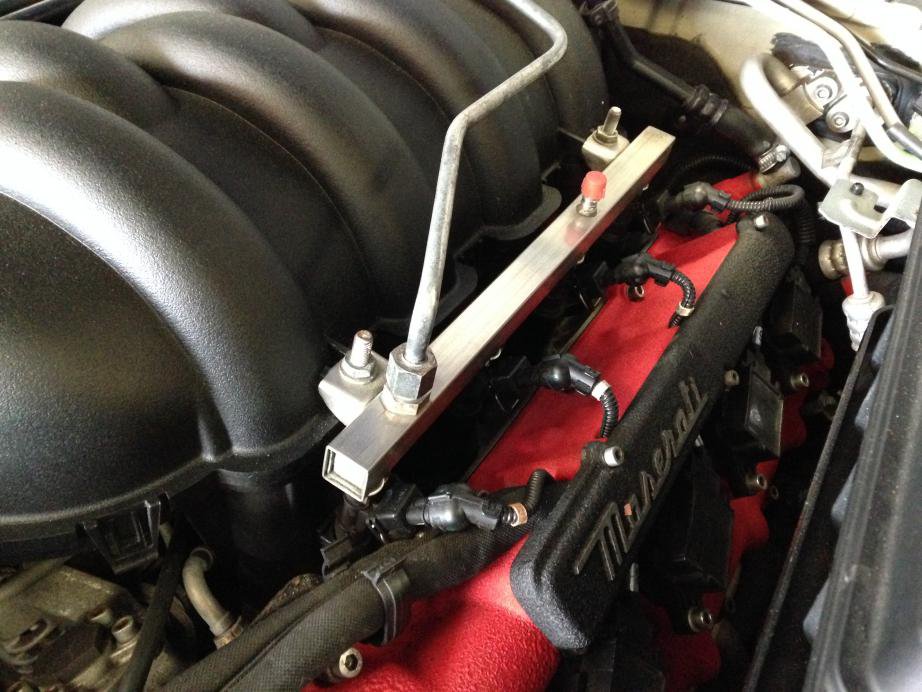

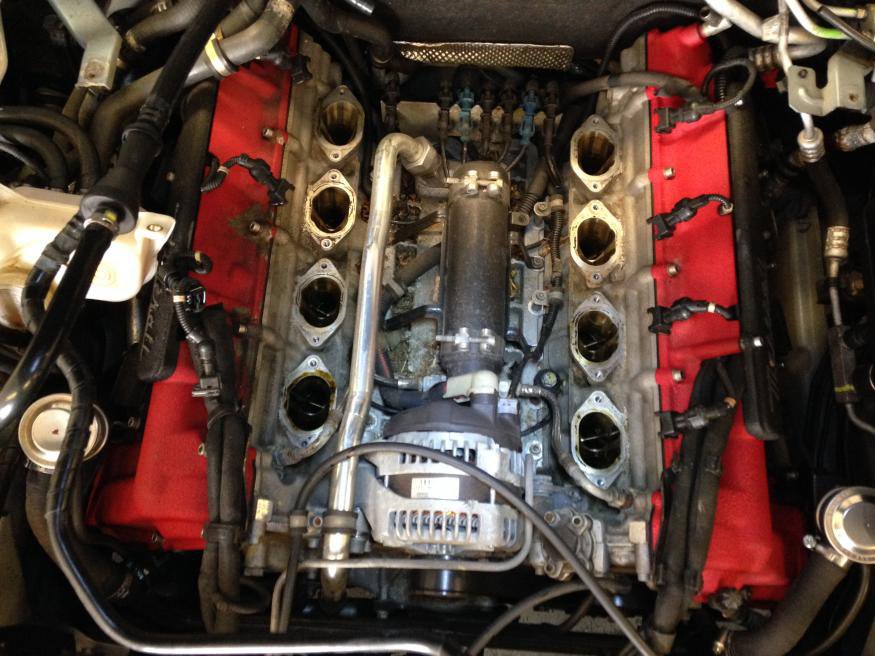

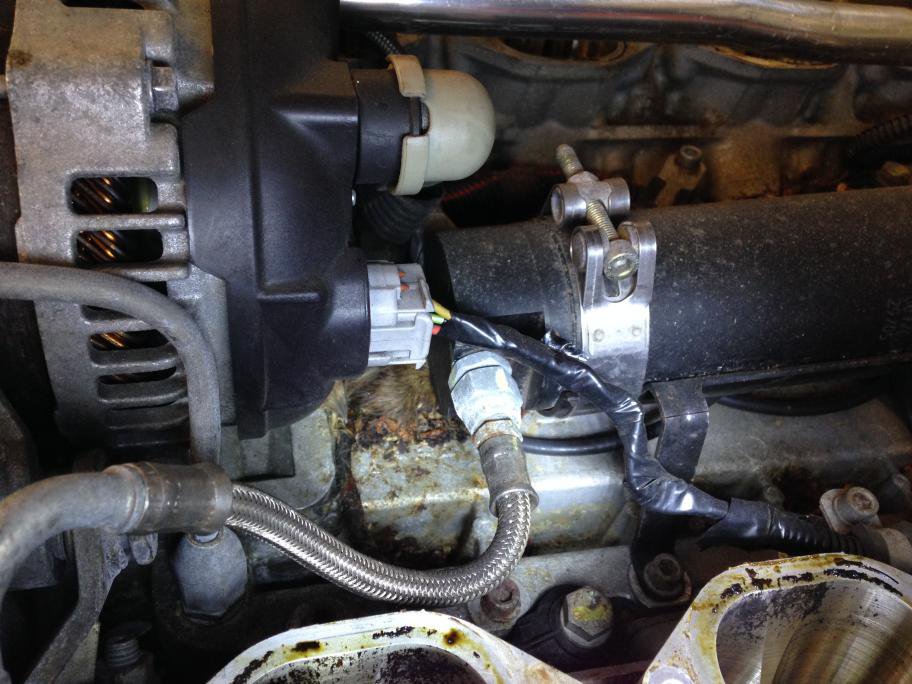

This is how hard it was......

So since I bought my QP back in March it has never been "right". The power delivery wasn't as smooth as I expected, the clutch control was terrible when it was cold, the throttle had very little connection with the engine when it was cold & it wouldn't rev past 5500 rpm. When it was hot it was better, but only better not right. It felt like it was down on power, not by much but didn't have that "vigour" I was expecting.

As this was my first QP V I reluctantly put it down to being how it was supposed to be.....but then common sense kicked in & there is no way Maserati would release a car with these characteristics.

I took it to Vince@ Migliore Cars for him to give it a once over & he agreed with the lack of revs but felt all else was ok.

He carried out a free diagnostic check which found that the knock sensor was faulty. He cleared the fault & we left it at that. Last month I had enough so I contacted him again so he could get to the bottom of the fault as it was no longer any fun.

Unfortunately he was going away on holiday the following week & would be busy before & after his holiday so I reluctantly booked it in at Graypaul in Solihull.

They had it for a couple of days & they came back with the same diagnosis, the knock sensor was faulty. I asked how much to remove & replace & was quoted £1478 for parts & labour!

I brought the car back whilst I pondered what to do. I decided to do the job myself, how hard could it be?

This is how hard it was......