You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Changing the oil pressure sensor

- Thread starter Dave

- Start date

Good news .....bad news

The jobs done and full instructions passed to Matt for others to use.

Bad news……..starting the car reveals a misfire, no oil pressure and a very rattly motor. I guess that there may be air in the fuel rails that would bleed out and cure the misfire. The oil supply was not disturbed so there should be nothing there but I’ve had to walk away....... again. More tomorrow.

More info on the new sensor it reads 10ohm at atmospheric, about 40ohm at 2 bar and about 80ohm at 5bar allowing for the course accuracy of my compressor pressure gauge.

The jobs done and full instructions passed to Matt for others to use.

Bad news……..starting the car reveals a misfire, no oil pressure and a very rattly motor. I guess that there may be air in the fuel rails that would bleed out and cure the misfire. The oil supply was not disturbed so there should be nothing there but I’ve had to walk away....... again. More tomorrow.

More info on the new sensor it reads 10ohm at atmospheric, about 40ohm at 2 bar and about 80ohm at 5bar allowing for the course accuracy of my compressor pressure gauge.

Last edited:

Panic over

Triple checked everything and tried again. With an overdoses of temerity I started it. Within seconds the pressure went to 5 bar, I left it running and everything went smooth and quiet. The rattle was the hydraulic tappets running empty, maybe insufficient valve operation leading to the misfire. I just didn't like the noise and switched the engine off very quickly. The two previous start ups helped prime the oil. So perhaps my suspicions are confirmed ie the oil accumulator had drained down and it was taking a few moments to fill up again. A bit like holding your thumb over a pipette full of liquid....lift your thumb and it all runs out. Removing the sender was like lifting your thumb. Now I can sleep tonight !

Triple checked everything and tried again. With an overdoses of temerity I started it. Within seconds the pressure went to 5 bar, I left it running and everything went smooth and quiet. The rattle was the hydraulic tappets running empty, maybe insufficient valve operation leading to the misfire. I just didn't like the noise and switched the engine off very quickly. The two previous start ups helped prime the oil. So perhaps my suspicions are confirmed ie the oil accumulator had drained down and it was taking a few moments to fill up again. A bit like holding your thumb over a pipette full of liquid....lift your thumb and it all runs out. Removing the sender was like lifting your thumb. Now I can sleep tonight !

Here is the inside of the old sender. There is a sealed piston plunger which pushes up onto a pivoting/rotating arm. One side "G" runs across a variable resistor, the other is a switch that opens above O bar. A tension spring returns the arm when the pressure reduces. 5 bar is halfway across the resistor, there is a visible wear/polish mark where the wiper has slid across and back a few hundred times. As I played with it, occasionally it started to stick about 2.5 bar (1/4 way) but I could see no reason for it. The wiper was catching on something............maybe the resistor is cracked and misaligned. I'll get a magnifier on it. Seems a bit complex for what it does but perhaps the radial movement along the resistor (about 20mm) is needed - thought a straight plunger on a compression spring would have been enough.

Attachments

How to change oil pressure sender

Matt has kindly played with the "how to..." and here is the link to it. Thanks Matt. If anyone wants further info I'm happy to help.

http://www.sportsmaserati.co.uk/showthread.php/7556-4200-oil-pressure-sender-removal

Matt has kindly played with the "how to..." and here is the link to it. Thanks Matt. If anyone wants further info I'm happy to help.

http://www.sportsmaserati.co.uk/showthread.php/7556-4200-oil-pressure-sender-removal

CB_Mas

New Member

- Messages

- 3

Hello, I'm new here, but figure to introduce myself with a posting on this topic.

The sender acted in a fashion apparently well known to this forum, but not to me, and was certainly anxiety and buyer's remorse inducing. No worry, we really enjoy and like this car, aside from it's various electrical gremlins. First target was the oil pressure sender, which only read 0 or 35 or 70psi or displayed a random needle dance with flashes of the oil pressure warning lights (gauge and center light).

As has been posted the terminals are exposed and the mechanical sender is fragile. It's a German (VDO) item used by Volkswagen, Ferrari, Maserati and probably many others. 0-10Bar range, with a .75Bar switch to ground on the WB terminal (unused in the 4200GT).

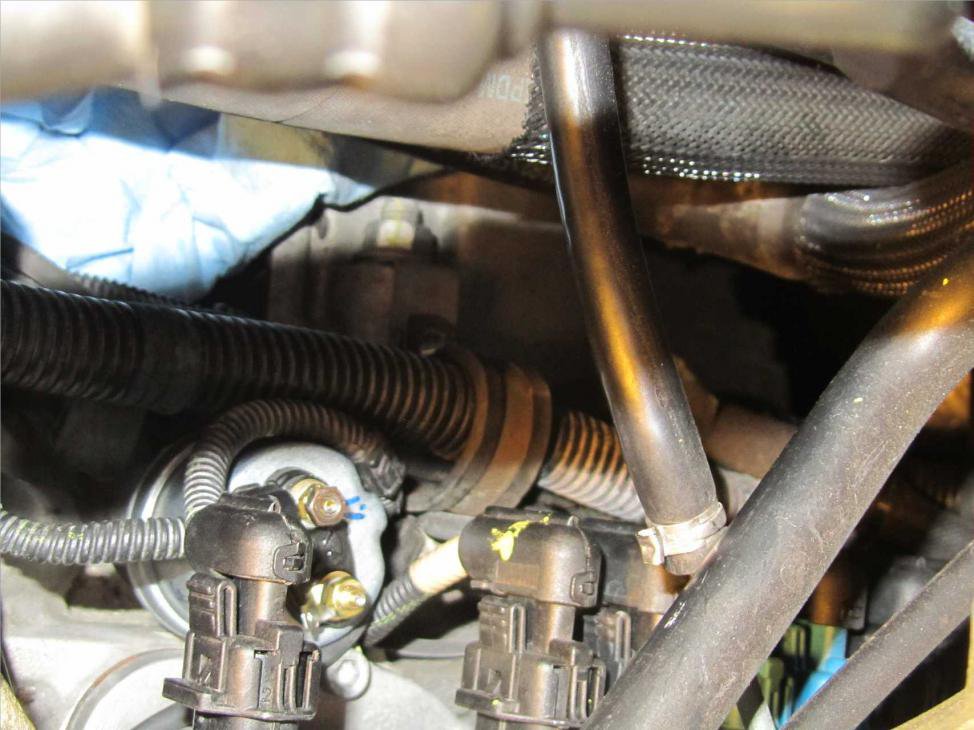

Key to removing it without disturbing the manifold, was a removal tool without slop. A standard crow's foot is too large, but milling (or grinding) one from 3/4" up to 24mm gives the right outer dimensions to fit in the minimal space. Next is to remove the slop between the 3/8" wrench extension and the crow's foot with either metal or electrical insulation tape (I used two layers over the extension end) and hammer the extension into the crow's feet. Remove three wire harness bolts, one is the nut on top near the bellhousing to the right of the clutch observation opening, the other two are on the back of the left cylinder bank. One of them blind (I used a mirror).

Loosening those allows enough movement of the wiring harnesses to place the removal tool. Careful not to pinch or crunch the crank sensor wiring, which should not be removed.

A two foot breaker bar using a 3/8" - 1/2" adapter was sufficient to crack it loose. If the slop is not removed, no amount of breaker bars or extension pipes or force will move this item, as noted by previous posters.

The sender acted in a fashion apparently well known to this forum, but not to me, and was certainly anxiety and buyer's remorse inducing. No worry, we really enjoy and like this car, aside from it's various electrical gremlins. First target was the oil pressure sender, which only read 0 or 35 or 70psi or displayed a random needle dance with flashes of the oil pressure warning lights (gauge and center light).

As has been posted the terminals are exposed and the mechanical sender is fragile. It's a German (VDO) item used by Volkswagen, Ferrari, Maserati and probably many others. 0-10Bar range, with a .75Bar switch to ground on the WB terminal (unused in the 4200GT).

Key to removing it without disturbing the manifold, was a removal tool without slop. A standard crow's foot is too large, but milling (or grinding) one from 3/4" up to 24mm gives the right outer dimensions to fit in the minimal space. Next is to remove the slop between the 3/8" wrench extension and the crow's foot with either metal or electrical insulation tape (I used two layers over the extension end) and hammer the extension into the crow's feet. Remove three wire harness bolts, one is the nut on top near the bellhousing to the right of the clutch observation opening, the other two are on the back of the left cylinder bank. One of them blind (I used a mirror).

Loosening those allows enough movement of the wiring harnesses to place the removal tool. Careful not to pinch or crunch the crank sensor wiring, which should not be removed.

A two foot breaker bar using a 3/8" - 1/2" adapter was sufficient to crack it loose. If the slop is not removed, no amount of breaker bars or extension pipes or force will move this item, as noted by previous posters.

Attachments

Klive

Junior Member

- Messages

- 724

Yahoo, I've just down mine. (Please excuse the excitement following success).

A couple of points to note.

1. I can confirm it really is impossible to take the crank sensor out to get better access with the spanner and as a consequence,

2. The crows foot spanner must be no thicker than 8mm. I managed to use a standard 24mm that had been ground to this thickness.

Thanks to the previous posters it helped a lot.

A couple of points to note.

1. I can confirm it really is impossible to take the crank sensor out to get better access with the spanner and as a consequence,

2. The crows foot spanner must be no thicker than 8mm. I managed to use a standard 24mm that had been ground to this thickness.

Thanks to the previous posters it helped a lot.