lambertius

Banned

- Messages

- 341

So who would've guessed that I had another broken part on my car... The driver's side window reg has been busted since I bought it. At some point in the past it was repaired - and badly. So I've picked a regulator off of a wrecker, and I've dismantled and reassembled it reinforced to replace whatever dodgy repair is on the existing regulator. I didn't want to pull the other one out and try and shove the tooth paste back in the tube.

If the driver's side one goes well, I'll make a video of the passenger side so that there is a clear step by step on everything that I did. To begin with I followed some of what is on Craig Waterman's page:

http://craig-waterman.com/?tag=maserati-window-regulator

A key difference is that I bought a couple of these repair pins - they're made by a forum member on the other forum. He has been super helpful.

https://www.ebay.com.au/itm/Maserat...ndow-Regulator-Repair-Pin-Pair-2/173960767103

I cut off the existing centre pin:

I've since fitted the new pin. It has a bit of play in it when there is only a bit of tension on the spring, but as the spring loads up the play gets taken up. I'll see how it goes - but I may end up getting the pin welded in place.

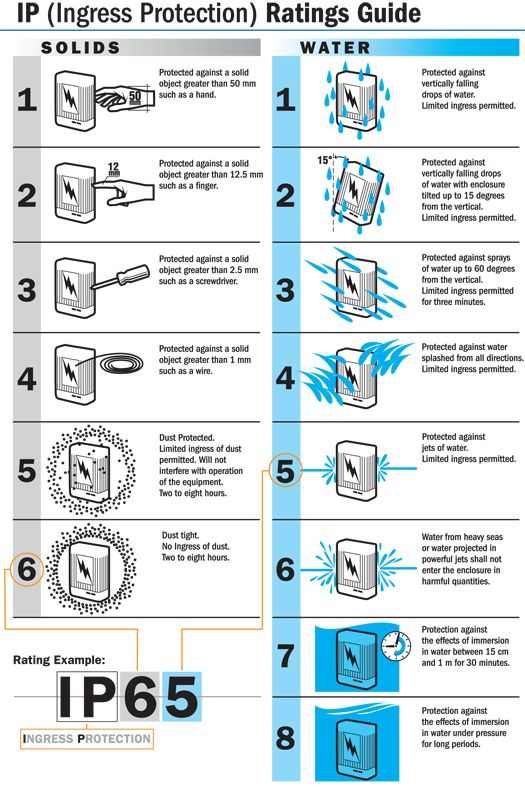

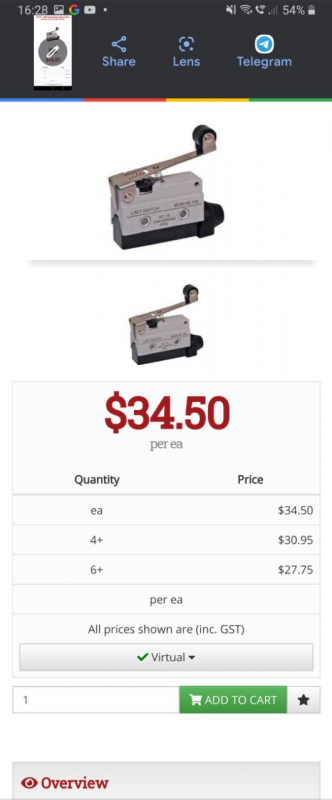

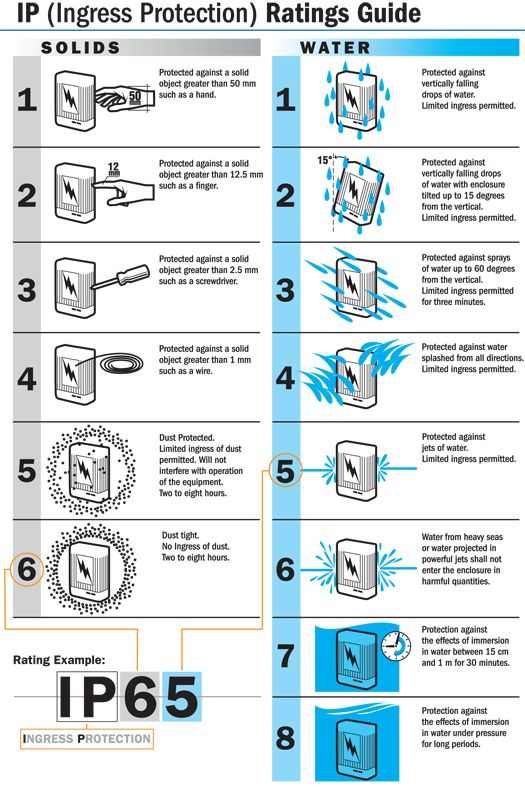

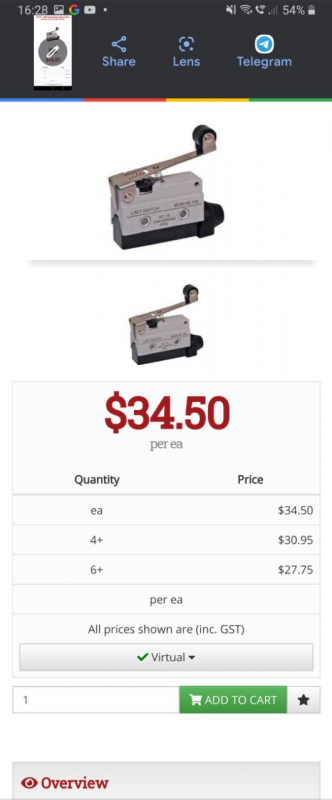

I'm still searching for a suitable microswitch as well. I was trying to find something with an IP6X rating so that the switch will never fail again in the future, but so far all the suitably rated switches I've found have a different mounting pattern than a standard microswitch.

I'll also be getting the gear itself welded up tomorrow to make sure it doesn't flex.

It will all get installed in the car over the coming weeks, and I'll report back!

If the driver's side one goes well, I'll make a video of the passenger side so that there is a clear step by step on everything that I did. To begin with I followed some of what is on Craig Waterman's page:

http://craig-waterman.com/?tag=maserati-window-regulator

A key difference is that I bought a couple of these repair pins - they're made by a forum member on the other forum. He has been super helpful.

https://www.ebay.com.au/itm/Maserat...ndow-Regulator-Repair-Pin-Pair-2/173960767103

I cut off the existing centre pin:

I've since fitted the new pin. It has a bit of play in it when there is only a bit of tension on the spring, but as the spring loads up the play gets taken up. I'll see how it goes - but I may end up getting the pin welded in place.

I'm still searching for a suitable microswitch as well. I was trying to find something with an IP6X rating so that the switch will never fail again in the future, but so far all the suitably rated switches I've found have a different mounting pattern than a standard microswitch.

I'll also be getting the gear itself welded up tomorrow to make sure it doesn't flex.

It will all get installed in the car over the coming weeks, and I'll report back!