Many thanks everyone for giving there input on this

In the hope it may help others I have done a little 'how- to' guide below

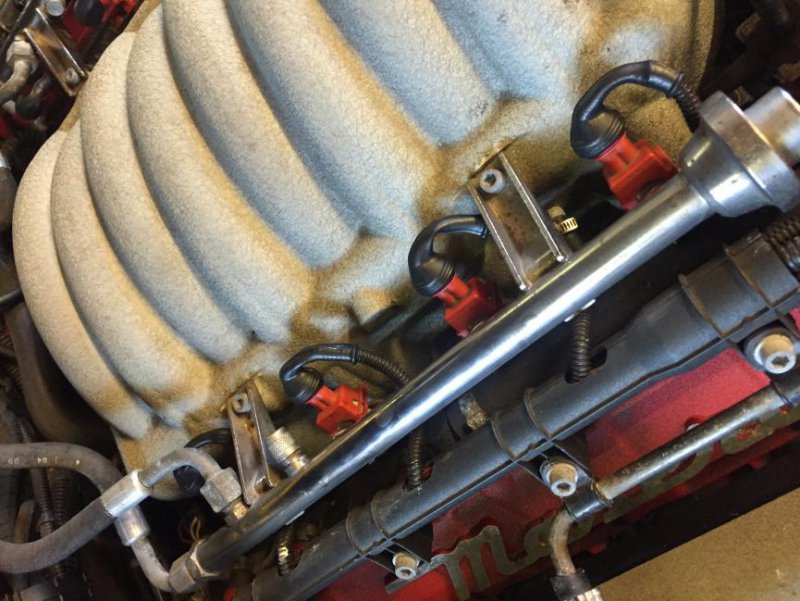

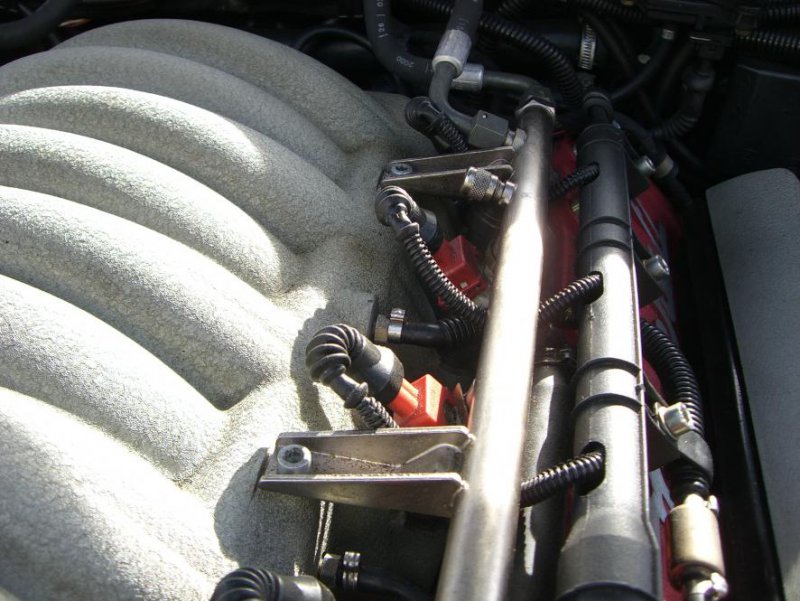

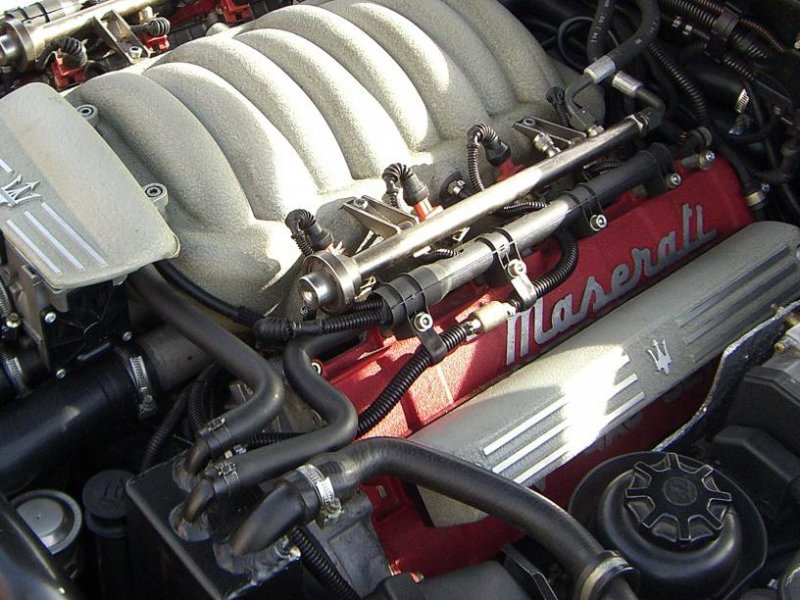

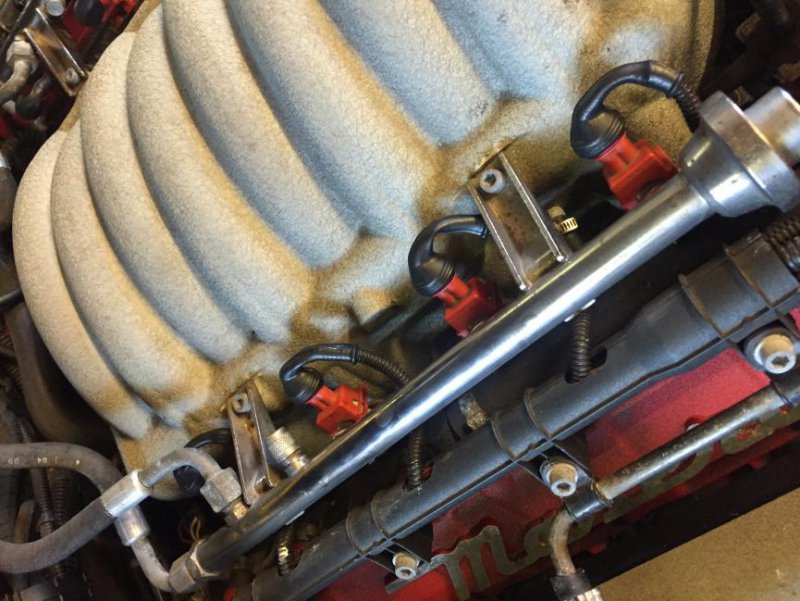

The rubber boots on the fuel injectors are very prone to split since they are straight boots which need to go around a sharp angle. They do spoil the look of the engine bay.

The replacement job is a bit fiddly but is straightforward and needs a couple of very low cost household ‘tools’.

1st of all buy 10 (eight require plus couple of spares) 90 degree boots at the link below for ~£1 each + postage.

http://www.vehicle-wiring-products.eu/product.php/591/angled-boot-for-2-pole-female-connector

These guys can also provide replacement plugs and other parts if required.

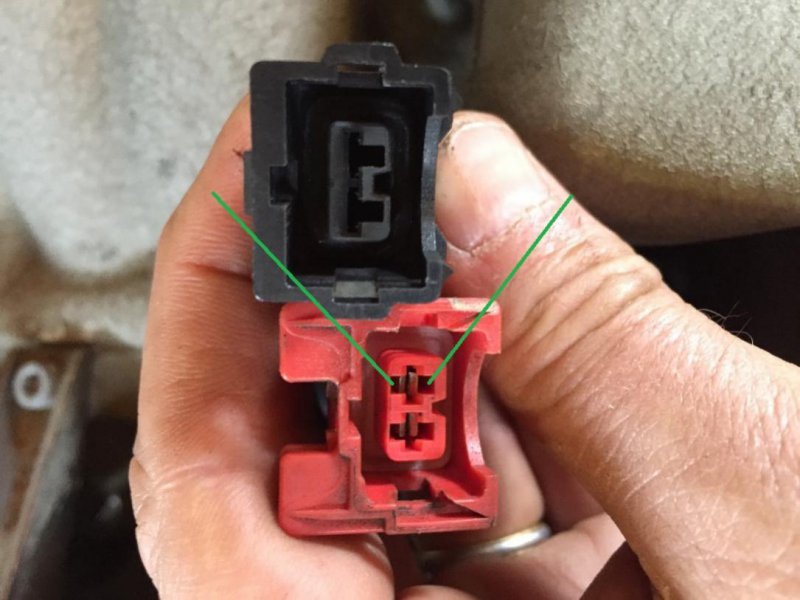

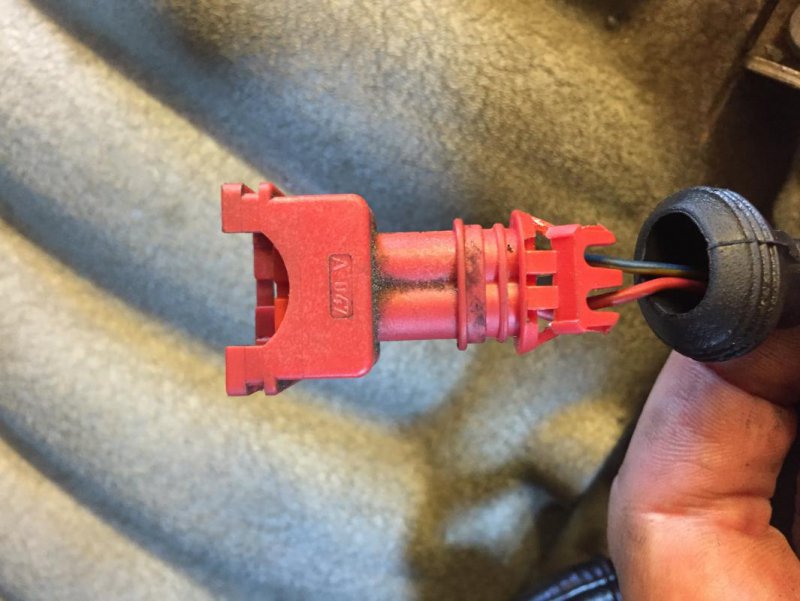

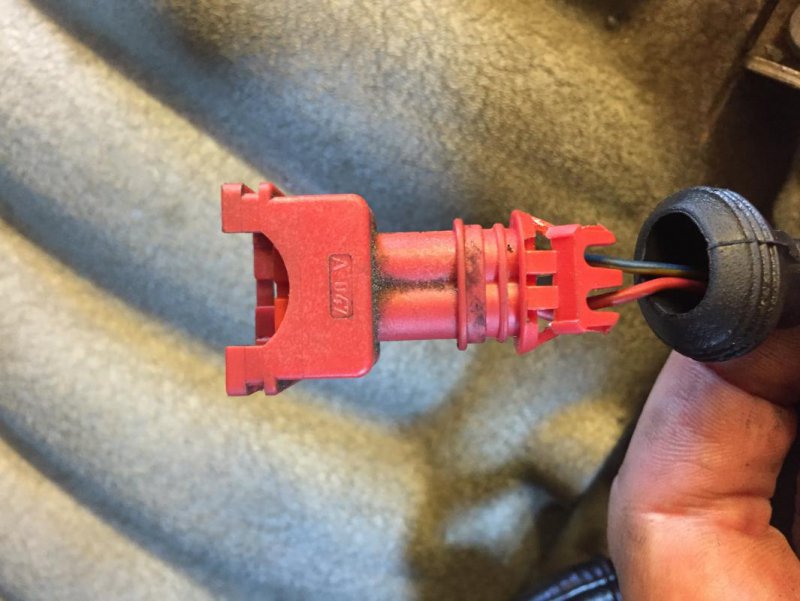

To remove the plug, pull out the retaining clip at its base and they just slide up.

Pull back the old rubber boot to reveal the back of the plug. There is a hinged clip on the rear of the plug which can be gently prised open with a small screwdriver.

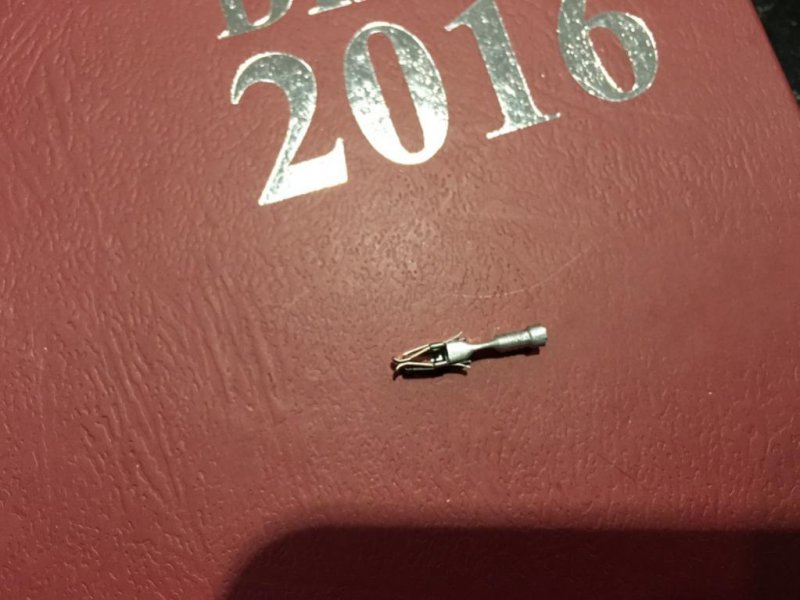

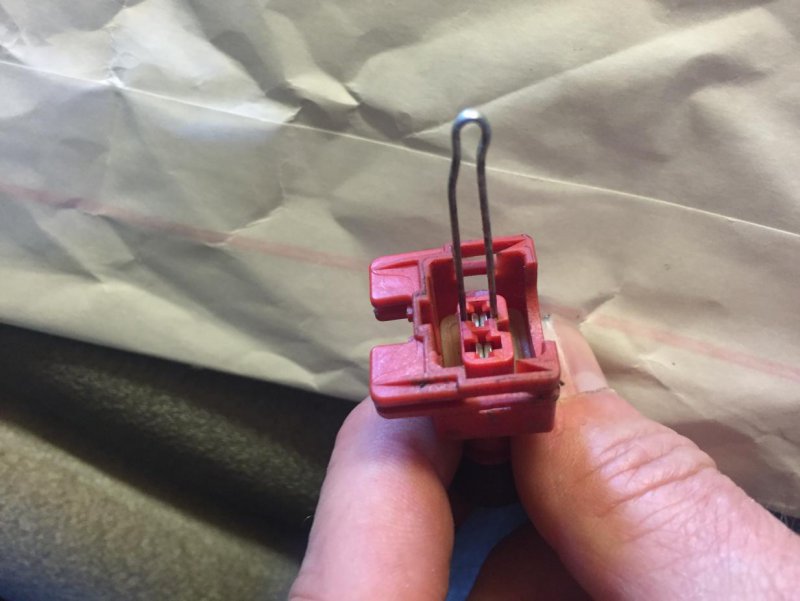

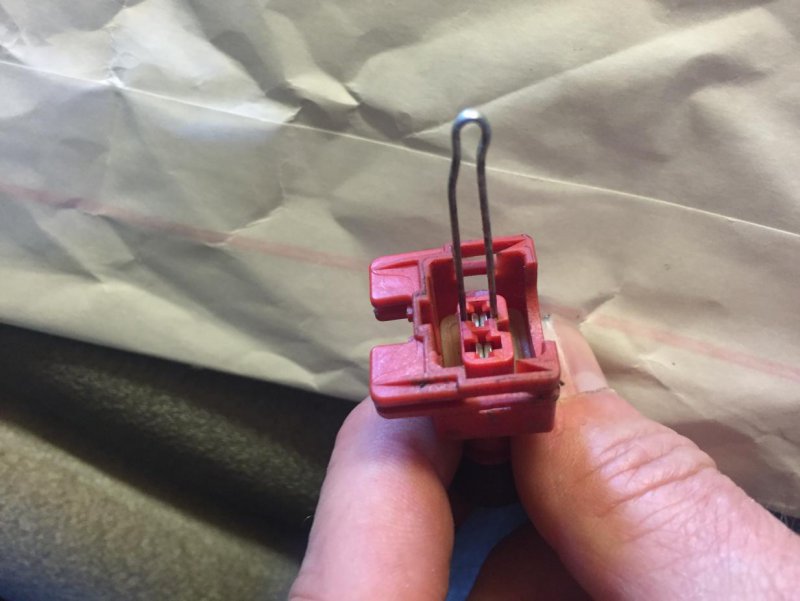

There are two leads with end terminal which are secured into the plug with internal clips. To remove these take a paperclip or split pin and bend so you have a two pronged tool.

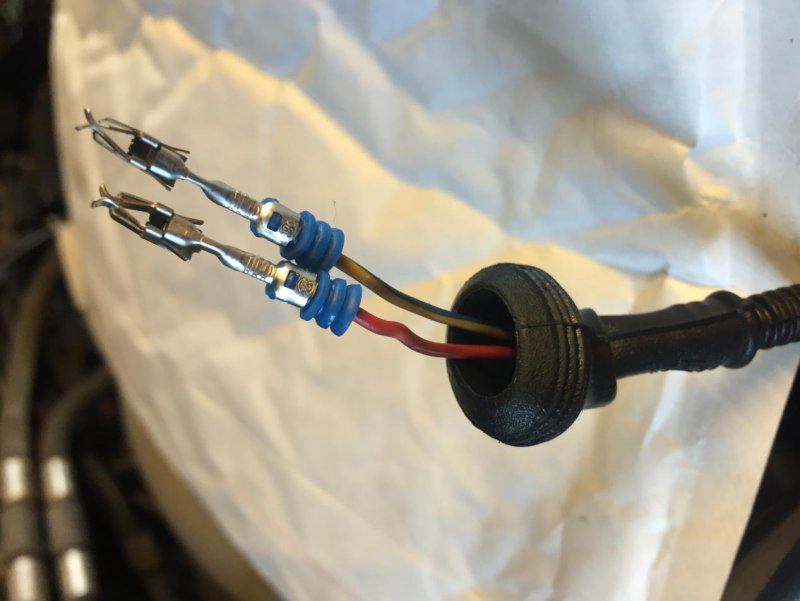

Gently push each lead forward to take any load off the locking tag, firmly push the split pin/paperclip into the end of the plug above and below the terminal and then gently pull on the lead at the rear of the plug and the terminal and blue sealing tab will slide out of the back of the plug.

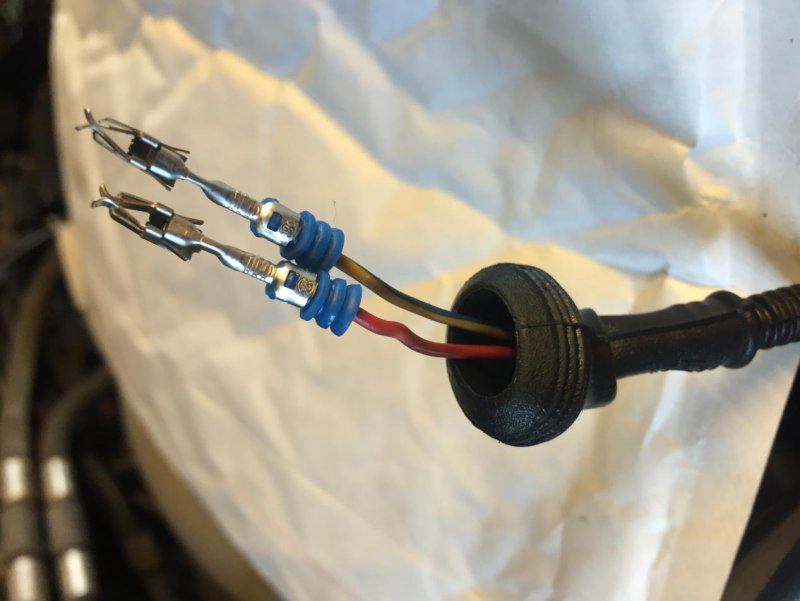

You will notice the new boots are of a smaller diameter which causes a minor problem in threading the wires through the thinner boot and around the 90 degree bend. It is also a bit more tricky to push the sleeving of the wires into the boot to seal the non plug end.

I took an old pen with a detachable pointed nose. Cut off a short section. Push this through the boot with the point and end and then remove the nose. The wires can then be simply pushed through the pen and boot.

At the non-plug end roll the boot back a couple of cm at the end, push the end of the old pen against the sleeving and roll back the boot over the sleeving. Viola job done. Then just gently extract the pen tube.

To reinsert the terminal, you simply feed them back into the plug ensuring the lock tabs are aligned correctly. Make sure the red wire goes to the left hand side of the plug as you view the plug with the round cut out facing you. Check that the terminals are fully pushed in and gently pull on each lead to ensure they are locked back in place. Then push the rear tab down to click back into place.

Then simply re attach each plug, pushing the retaining clip into place and align the bend of the boot so it smoothly follows the desired wiring direction.

As I say a bit fiddly, but shiny new boots within 1 hour …..