Lewis Gregory

Junior Member

- Messages

- 39

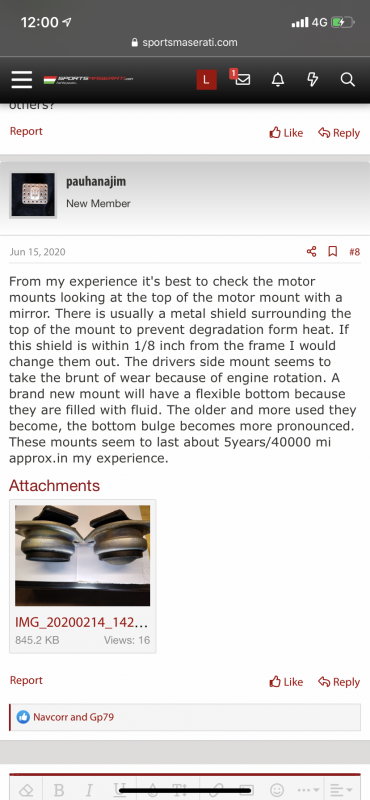

IIRC the only difference between the Quattroporte engine mount and 4200 transmission mount is the metal plate on top of the mount, which can be unscrewed and reused from the old one.

The GranTurismo transmission mount has the same mounting plate as the 4200 mount, but I think the rubber itself is taller overall.

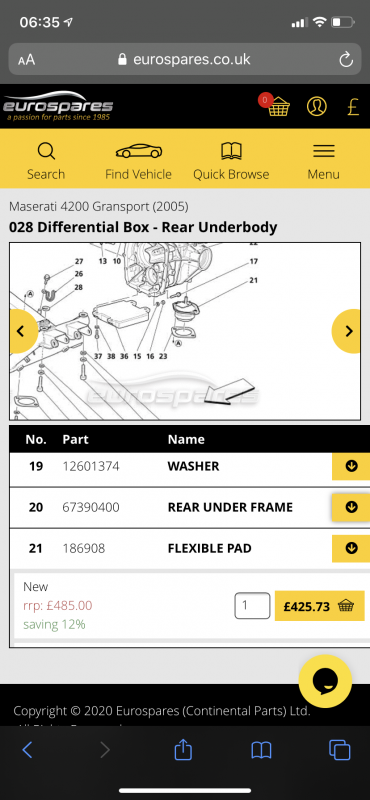

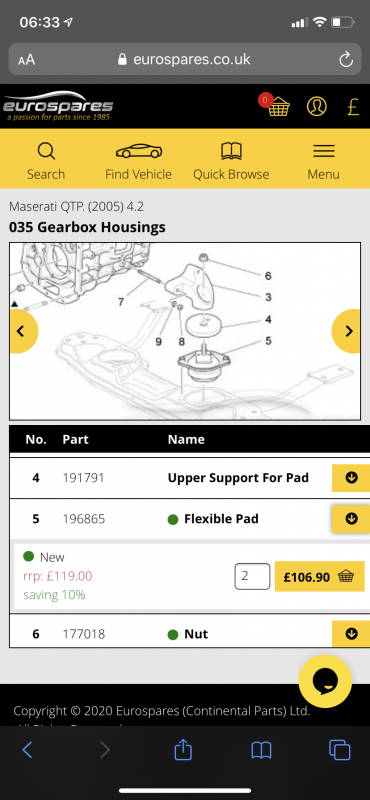

I would like to confirmation about the gearbox mount, as if true there is a substantial saving there. The 4200/Gransport mount is about £500, wear as the quatrroporte mount is just over £100. It looks like the QP uses two mounts though, so not sure if it would be the same as the GS/4200?