Chris155

Member

- Messages

- 196

Thread update.

MOT passed, No advisories.

Screenshot 2020-10-24 at 01.43.38 by Chris, on Flickr

Screenshot 2020-10-24 at 01.43.38 by Chris, on Flickr

Pleased with that.

And as I alluded to in one of my recent posts, I've had the exhaust modified.

This thought process started shortly after I acquired the car, I was offered a Larini 'x' pipe for £350. I went off and researched it and found that most people regard it as a worthwhile, almost essential change.

However, nicely welded, the larini part is, in my view it is not worth the asking price, new or 2nd hand. Thusly, I decided to embark on a voyage of welding discovery...

I have a MIG welder that I've not really mastered but I investigated welding Stainless steel using it and, based on internet advice, dismissed it as unviable. I'm not sure why but IIRC it's difficult to get a decent weld and the gas is expensive?

Anyhoo, I decided to buy the cheapest centre box I could find on eBay with the intention of chopping it up for £65. I figured I could chop off the X pipe section and remake the rest using sleeved joints, some straight pipe and some clamps.

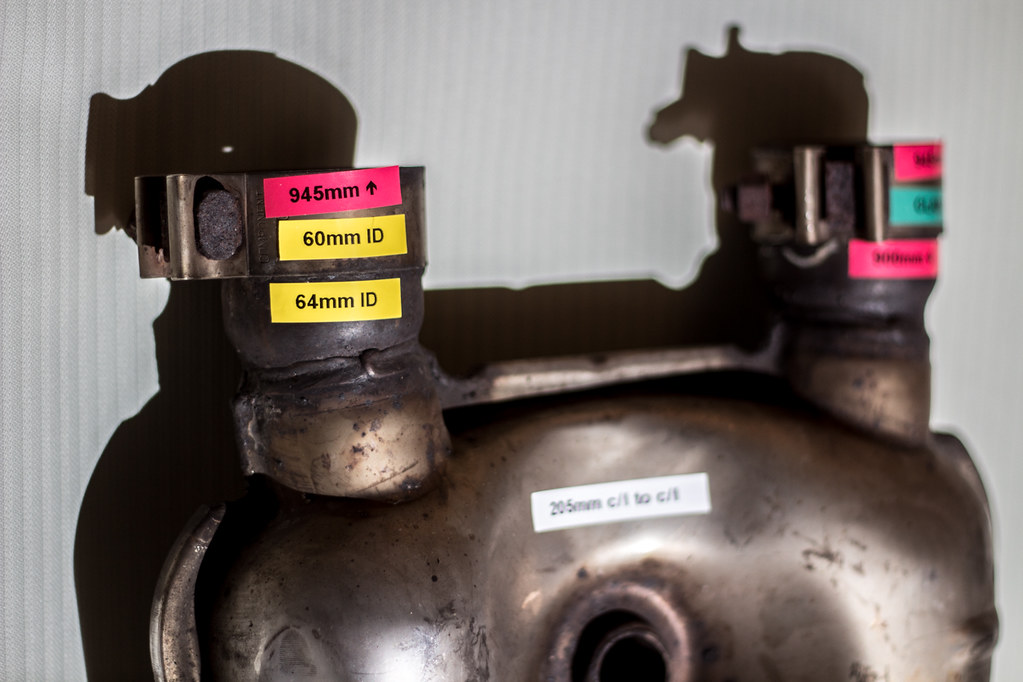

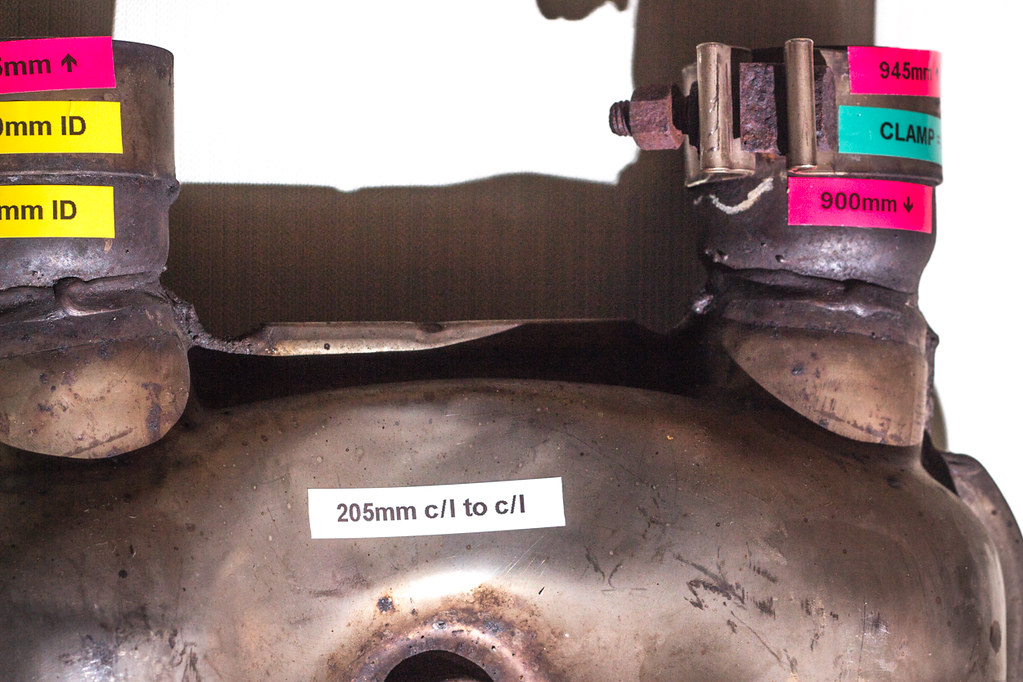

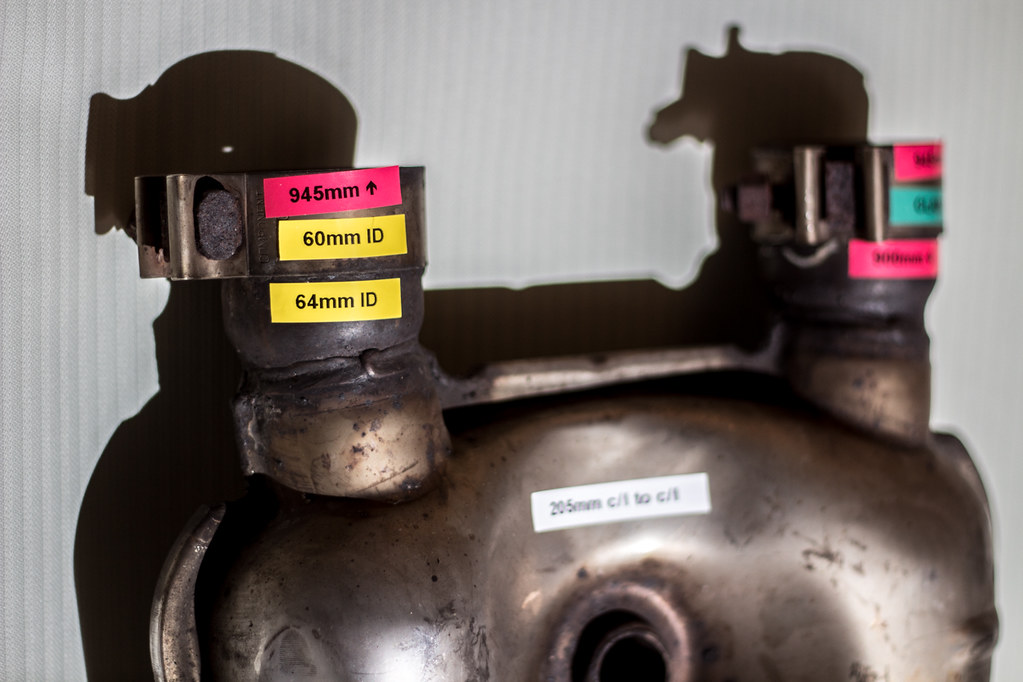

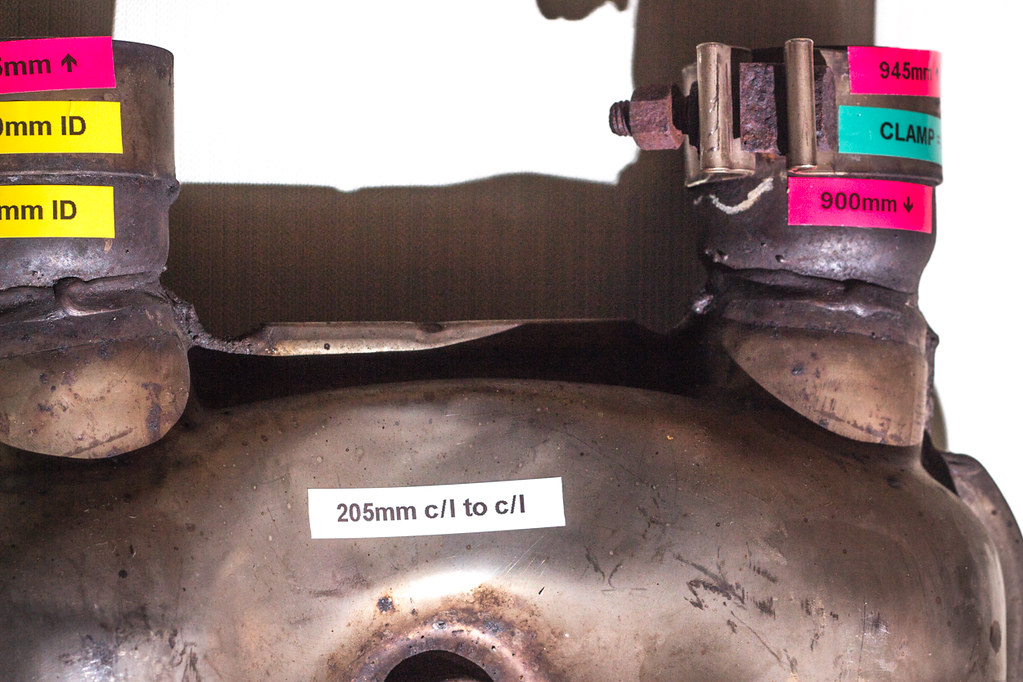

I started off by taking some measurements and labelling the exhaust up (using the base of the x pipe as a datum for length) IDs, ODs and CL distances (Thank you Bad Obsession M/sport for showing us how to accurately find the CL distance)...

IMG_0788 by Chris, on Flickr

IMG_0788 by Chris, on Flickr

IMG_0799 by Chris, on Flickr

IMG_0799 by Chris, on Flickr

IMG_0796-2 by Chris, on Flickr

IMG_0796-2 by Chris, on Flickr

IMG_0789 by Chris, on Flickr

IMG_0789 by Chris, on Flickr

IMG_0792 by Chris, on Flickr

IMG_0792 by Chris, on Flickr

IMG_0794 by Chris, on Flickr

IMG_0794 by Chris, on Flickr

At this point, I was feeling confident I could make something up as planned using an eBay pipe bender like this;

However, I the realised it's not just the C/L difference end to end that I'd have to account for in the horizontal plane, it's also convex, bending upwards in the vertical plane, presumably to gain ground clearance;

IMG_0806 by Chris, on Flickr

IMG_0806 by Chris, on Flickr

IMG_0818 by Chris, on Flickr

IMG_0818 by Chris, on Flickr

Placing it upside down probably shows this better?

IMG_0810 by Chris, on Flickr

IMG_0810 by Chris, on Flickr

IMG_0817 by Chris, on Flickr

IMG_0817 by Chris, on Flickr

At this point, I stated questioning whether it was viable in the practical sense and worthwhile financially. Yes I'd gain a pipe bender out of it butIt'd be a PITA to store and it wouldn't be something I'd use often.

Coincidentally, my Dad had taken my mother's Brera to an exhaust fabricator for a new centre section as they can't be sourced easily in the meanwhile. I ended up chatting with the Farbicators about their cars and decided to ask then for a quote to remake the centre box with straight pipes for me.

I ended up going with this option as it cost £130. Bringing the total cost to £200. But I also have the original centre box should I choose to revet back to standard. I suppose that I could sell this for around £100 if I chose to.

Sound wise, it's not much louder, as the internet suggested. What I really like is that the exhaust crackles are now more pronounced - valve overlap, as an engine should sound, not the pretend manufactured nonsense most fast VAG products have.

I'm really pleased with the result in spite of the fact I chickened out out on making it myself.

MOT passed, No advisories.

Screenshot 2020-10-24 at 01.43.38 by Chris, on Flickr

Screenshot 2020-10-24 at 01.43.38 by Chris, on FlickrPleased with that.

And as I alluded to in one of my recent posts, I've had the exhaust modified.

This thought process started shortly after I acquired the car, I was offered a Larini 'x' pipe for £350. I went off and researched it and found that most people regard it as a worthwhile, almost essential change.

However, nicely welded, the larini part is, in my view it is not worth the asking price, new or 2nd hand. Thusly, I decided to embark on a voyage of welding discovery...

I have a MIG welder that I've not really mastered but I investigated welding Stainless steel using it and, based on internet advice, dismissed it as unviable. I'm not sure why but IIRC it's difficult to get a decent weld and the gas is expensive?

Anyhoo, I decided to buy the cheapest centre box I could find on eBay with the intention of chopping it up for £65. I figured I could chop off the X pipe section and remake the rest using sleeved joints, some straight pipe and some clamps.

I started off by taking some measurements and labelling the exhaust up (using the base of the x pipe as a datum for length) IDs, ODs and CL distances (Thank you Bad Obsession M/sport for showing us how to accurately find the CL distance)...

IMG_0788 by Chris, on Flickr

IMG_0788 by Chris, on Flickr IMG_0799 by Chris, on Flickr

IMG_0799 by Chris, on Flickr IMG_0796-2 by Chris, on Flickr

IMG_0796-2 by Chris, on Flickr IMG_0789 by Chris, on Flickr

IMG_0789 by Chris, on Flickr IMG_0792 by Chris, on Flickr

IMG_0792 by Chris, on Flickr IMG_0794 by Chris, on Flickr

IMG_0794 by Chris, on FlickrAt this point, I was feeling confident I could make something up as planned using an eBay pipe bender like this;

Heavy Duty Hydraulic Manual Exhaust Pipe Tube Bender Machine Bending Formers UK | eBay

Find many great new & used options and get the best deals for Heavy Duty Hydraulic Manual Exhaust Pipe Tube Bender Machine Bending Formers UK at the best online prices at eBay! Free delivery for many products!

www.ebay.co.uk

However, I the realised it's not just the C/L difference end to end that I'd have to account for in the horizontal plane, it's also convex, bending upwards in the vertical plane, presumably to gain ground clearance;

IMG_0806 by Chris, on Flickr

IMG_0806 by Chris, on Flickr IMG_0818 by Chris, on Flickr

IMG_0818 by Chris, on FlickrPlacing it upside down probably shows this better?

IMG_0810 by Chris, on Flickr

IMG_0810 by Chris, on Flickr IMG_0817 by Chris, on Flickr

IMG_0817 by Chris, on FlickrAt this point, I stated questioning whether it was viable in the practical sense and worthwhile financially. Yes I'd gain a pipe bender out of it butIt'd be a PITA to store and it wouldn't be something I'd use often.

Coincidentally, my Dad had taken my mother's Brera to an exhaust fabricator for a new centre section as they can't be sourced easily in the meanwhile. I ended up chatting with the Farbicators about their cars and decided to ask then for a quote to remake the centre box with straight pipes for me.

I ended up going with this option as it cost £130. Bringing the total cost to £200. But I also have the original centre box should I choose to revet back to standard. I suppose that I could sell this for around £100 if I chose to.

Sound wise, it's not much louder, as the internet suggested. What I really like is that the exhaust crackles are now more pronounced - valve overlap, as an engine should sound, not the pretend manufactured nonsense most fast VAG products have.

I'm really pleased with the result in spite of the fact I chickened out out on making it myself.

Last edited:

IMG_5411-2

IMG_5411-2 IMG_5412

IMG_5412 IMG_5413

IMG_5413 IMG_5414

IMG_5414 IMG_4784

IMG_4784 IMG_4769

IMG_4769 IMG_4781

IMG_4781 IMG_4796

IMG_4796 IMG_4798

IMG_4798 IMG_4764

IMG_4764 IMG_4763

IMG_4763 IMG_4758

IMG_4758 IMG_4757

IMG_4757 IMG_4766

IMG_4766 IMG_4767

IMG_4767 IMG_4760

IMG_4760

IMG_5588

IMG_5588 IMG_5557

IMG_5557 IMG_5551

IMG_5551 IMG_5555

IMG_5555 IMG_5720-2

IMG_5720-2 IMG_5723

IMG_5723 IMG_5725

IMG_5725 IMG_5726

IMG_5726 IMG_5727

IMG_5727 IMG_5732

IMG_5732 IMG_5729

IMG_5729 IMG_5728

IMG_5728 IMG_5735

IMG_5735 IMG_5737

IMG_5737 IMG_5739

IMG_5739 IMG_5742

IMG_5742 IMG_5744

IMG_5744 IMG_5746

IMG_5746 IMG_5745

IMG_5745 IMG_5748

IMG_5748 IMG_5751

IMG_5751 IMG_5752

IMG_5752 IMG_5763

IMG_5763 IMG_5798

IMG_5798 IMG_5799

IMG_5799 IMG_5803

IMG_5803 IMG_5808

IMG_5808 IMG_5811

IMG_5811 IMG_5834

IMG_5834 IMG_5836

IMG_5836 IMG_5838

IMG_5838 IMG_5839

IMG_5839 IMG_5842

IMG_5842 IMG_5843

IMG_5843 IMG_5844

IMG_5844 IMG_5850-2

IMG_5850-2 IMG_9659

IMG_9659 IMG_9634

IMG_9634 IMG_9627

IMG_9627 IMG_9621

IMG_9621 IMG_9618

IMG_9618 IMG_9606

IMG_9606 IMG_9603

IMG_9603 IMG_9600

IMG_9600 IMG_9596

IMG_9596 IMG_9579

IMG_9579 IMG_9574

IMG_9574 IMG_9572

IMG_9572 IMG_9568

IMG_9568 IMG_9567-2

IMG_9567-2 IMG_9555-2

IMG_9555-2 IMG_9552

IMG_9552 IMG_9736

IMG_9736 IMG_9725-2

IMG_9725-2 IMG_9717

IMG_9717 IMG_9710

IMG_9710 IMG_9707

IMG_9707 IMG_9701

IMG_9701 IMG_9699

IMG_9699 IMG_9696

IMG_9696 IMG_9694

IMG_9694 IMG_9691

IMG_9691 IMG_9686

IMG_9686 IMG_9683

IMG_9683 IMG_9681

IMG_9681 IMG_9675

IMG_9675 IMG_9667

IMG_9667 IMG_9658

IMG_9658