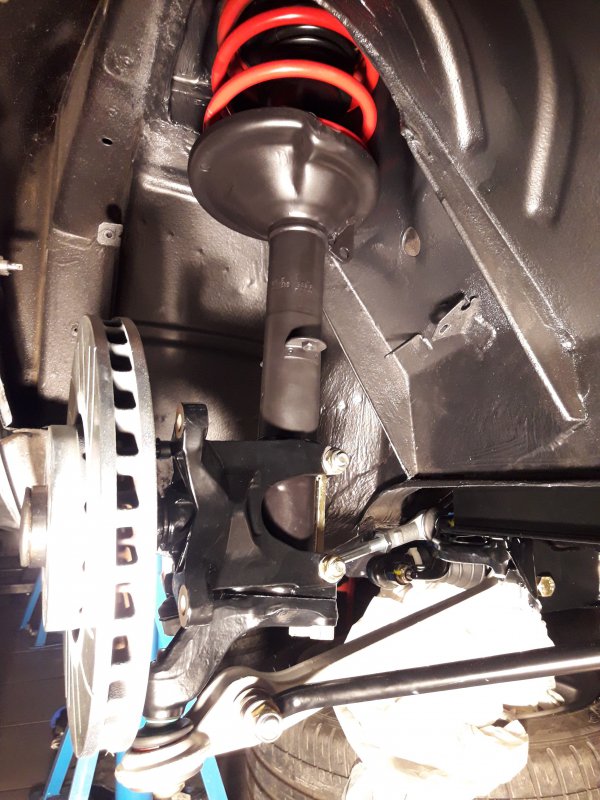

I haven't given any update lately, but I would like to present the front suspension I've finished earlier.

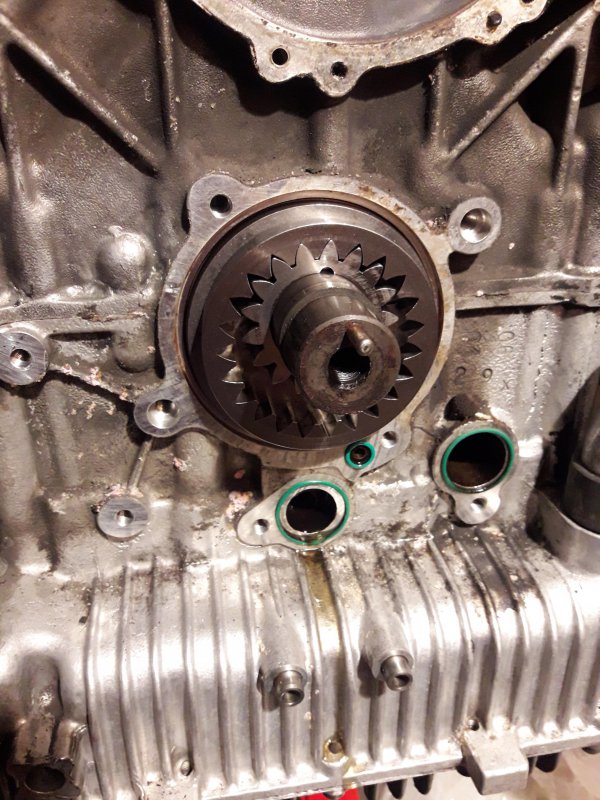

Since the shocks were already done, the next were the hubs

First I've installed the bearing on the stub axle because the workshop manual states this is only available as a preassembled part. Put a 42 wrench on the axle and made sure the ABS connector is parallel with the wrench. The alignment helps later so that the wrench will fit on the axle while mating the preassembled part to the hub carrier. Clamped the wrench in a vice and tightened down the bearing with a deep 36 socket. I've used Loctite 262 on the other threaded side of the stub axle, which connects it to the carrier. Originaly Loctite 271 was used (the red remains were still visible on the thread) which is unavailable, but based on the tech data 262 is pretty much the same (it's medium / high strength threadlocker). So when diassembling it's advised to heat up this nut.

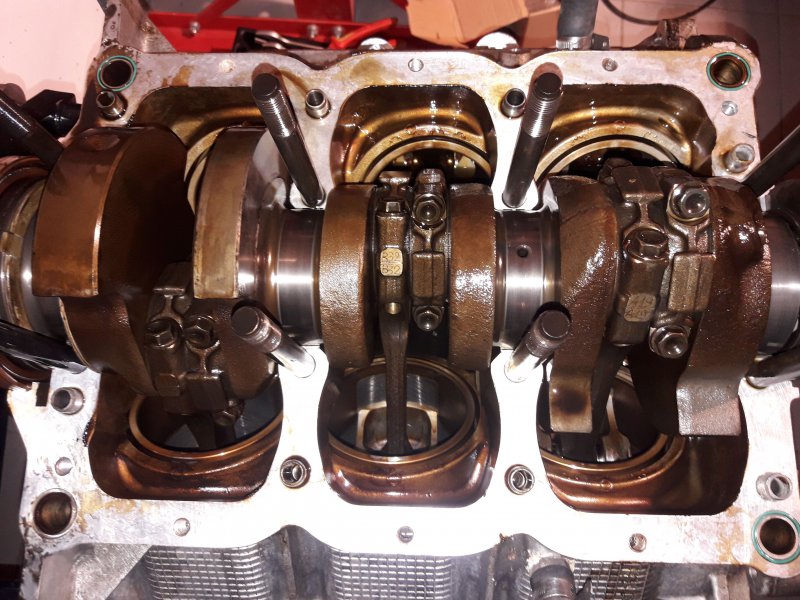

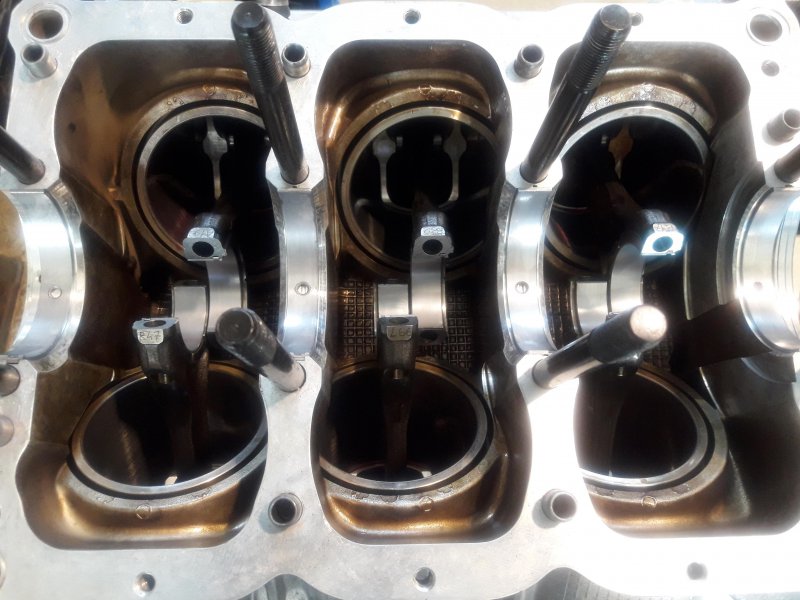

Both front hubs assembled

Finally hub installed on the shocks. This was pretty simple, there is only one way to do it

The steering rack was also pretty beat up, one of the bellow broken.

Cleaned up as much as possible, but the yellow zinc / cad (?) plating was corroded here and there so I got some colour matched paint (of course it's not plating) and painted (epoxy, base and clear) the main body. Replaced the bellows and while there the ball joints too.

The bearings in the steering arms were also replaced

The rubber joints connecting the control arms to the front of the subframe were also broken (the GT / QP4 uses a modified joint, probably to fight this issue) so I've also replaced these (sourced some leftover stock from '97)