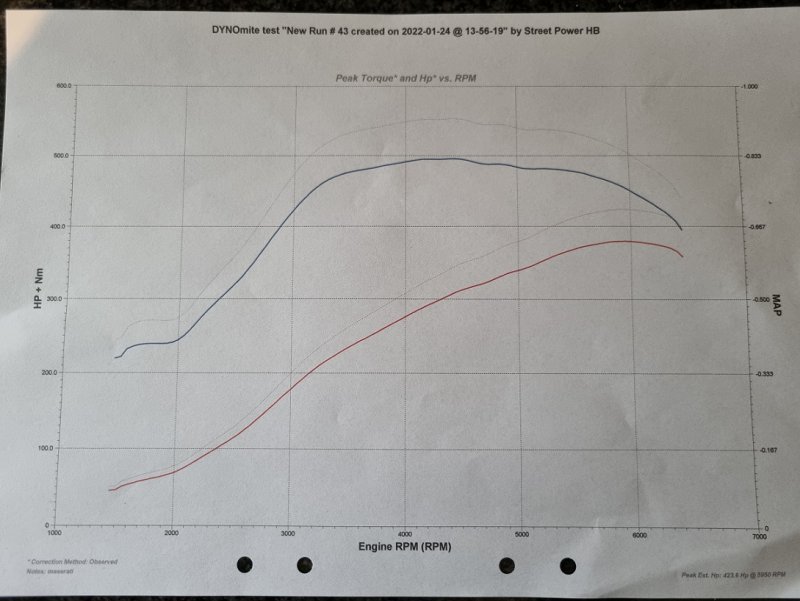

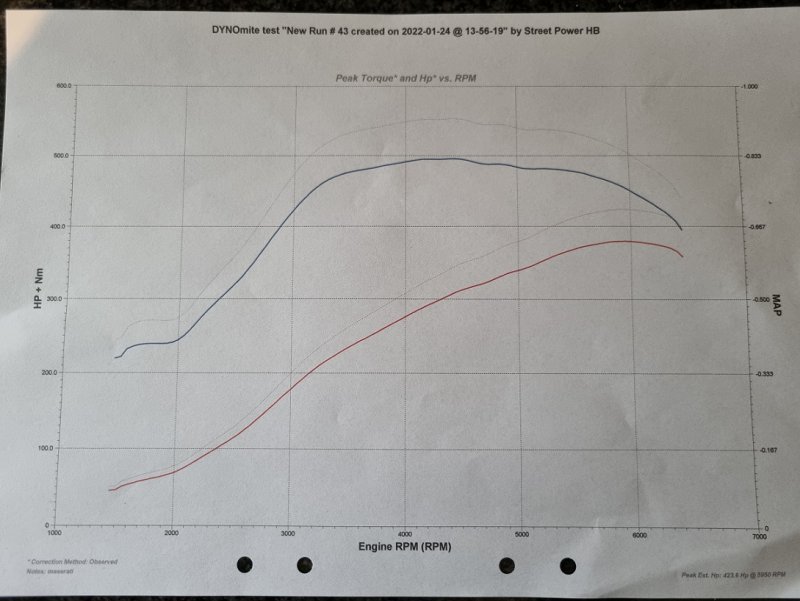

I have modified and tuned a friends Ghibli GT 2,8L -96 as much as possible without mechanical modifications of the engine and without anything visible from outside and with all equipment working as normal (AC, instruments and more) and the car should have drivability as a “normal¨ car. The engine was completely overhauled ca 7000 km´s ago. Specification: Fuel pump changed to Walbro 450, Intercoolers changed to QP4, Tubes from Turbo to IC increased from 41mm to 51mm diameter, same as IC inlet and outlet. Same for tubes from IC to manifold. Exhaust front part changed to Tubi with two 100 cell metallic catalysts, one for each side, rear exhaust is custom made 2 1/2” with one small straight through silencer on each side. Turbos are from 3200 Assetto Corsa. Clutch is Sachs Racing. Engine management system is changed to a MaxxEcu Race. The harness from the new ECU to the car was made as a plug-in harness so it attaches to the Cars harness instead of the Weber Marelli ECU´s. We use the car´s standard sensors only added a 60 -2 trigger wheel to pick up the rpm from the crankshaft. The SEM wastegate valve was changed to a MAC valve. Injectors was changed to Bosch EV14 714cc. Ignition modules was changed to fit the new ECU. Weber fuel pressure regulator was changed to one from AEM set to 3,5bar. One Bosch Lambda sensor LSU 4.2 on each side and one K-type temperature sensor in each exhaust manifold. Ethanol sensor so it is now a flex fuel car. The car was mapped and tested on a Dynomite Hub dyno. The car owner wants the engine to behave as much as possible as a NA engine so we held back the turbo pressure at lower RPM and increased it more and more with RPM to get the characteristic he wants. Otherwise, we could have got much higher torque on lower RPM. The results: On 98 Octan standard fuel; 379,2HP @ 6050 RPM (339,3 wheel HP) 514NM @ 4500 RPM (460,3 Wheel NM) max Turbo boost 1,4 bar. With E85 423,6 HP @ 5950 RPM (379,4 Wheel) 553,2 NM @ 4400 RPM (495,5 wheel) max turbo boost 1,5 bar. This was the absolute maximum the engine delivered, higher boost or changed ignition did not give anything more it was totally stop at this power output. Maximum injector opening time at E85 was 83%. The exhaust temp about max allowed 950 deg, almost hitting 1000 deg. With two deg higher (earlier) ignition pinging occurred at top RPM. Higher turbo boost did not give any more power eighter. Our conclusion is, this is the end for the small IHI turbos, they are too small, the turbine is probably to narrow and cannot let more exhaust out.