Keep it up what a fantastic effort from such a young lad

It only gets better from here

I think..

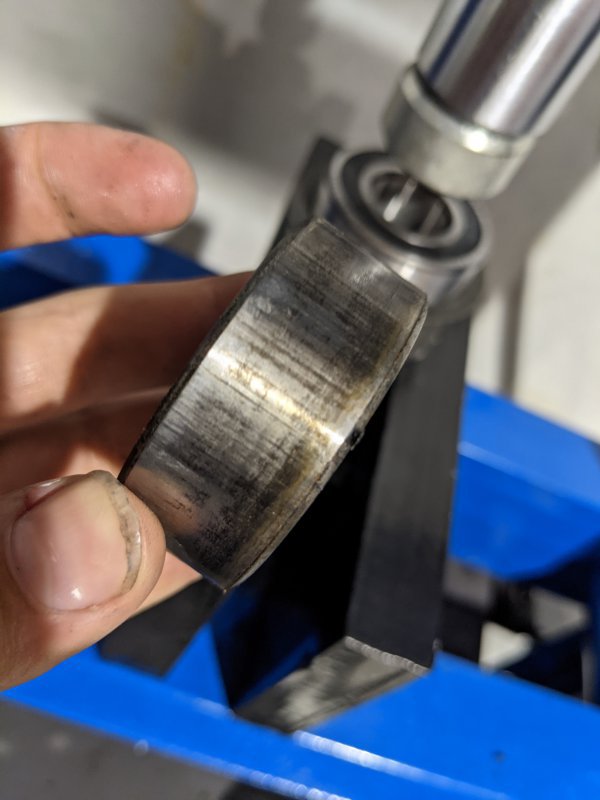

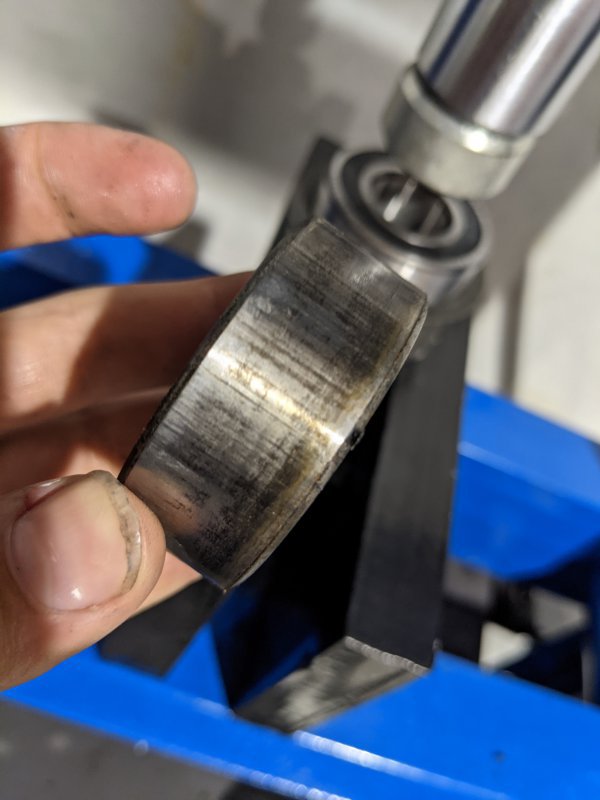

Wickedly enough, as soon as I arrived home I had access to a mate's brand new hydraulic press to swap the bearings out of their metal guide shells.

I attempted to do this prior to leaving for my trip, in a vice and that was to no avail. The press however, after a dozen pumps abruptly gave way and there I knew I had false hope of magically removing it with the vice or with any other piece of equipment haha

These Explorer bearings were cheaper to attain from Europe than anywhere locally in Australia, and I spent more than enough time hunting for the original SKF 633186A part just for the over extreme Dynamic capacity(C) that these are rated for. Again my understanding only contributes to the theoretical rotational life of the bearing. So a larger number would benefit to live a longer lifespan. But nobody has them sooooooooooooo

Bit of lithium grease and new ones pressed in for both housings. Might as well

July ->

Spent the month repairing my VW and bought another(as a quick project) as I've left it neglected for a little bit too long... This month was conclusion month for the engine shop too

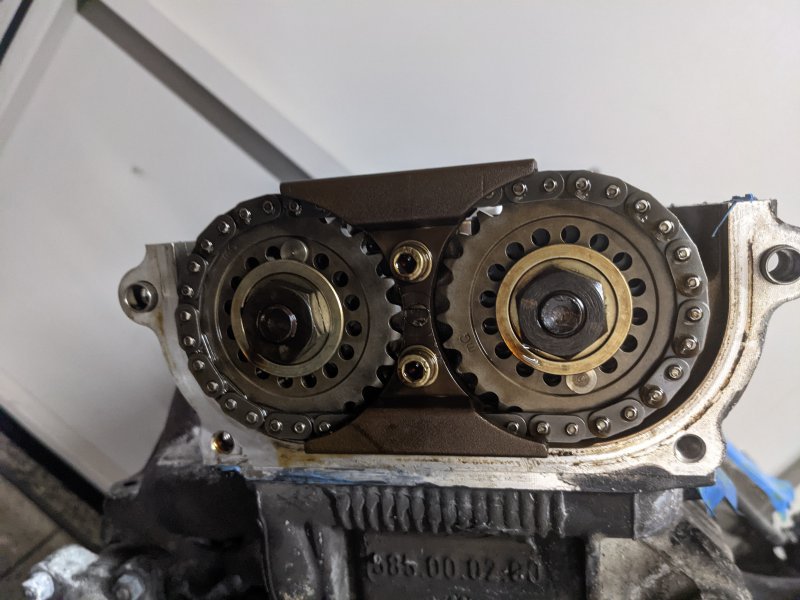

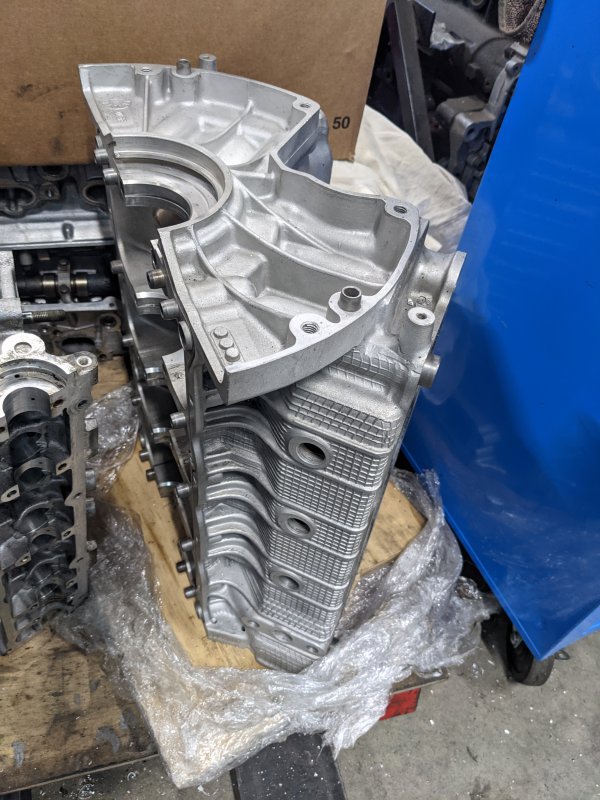

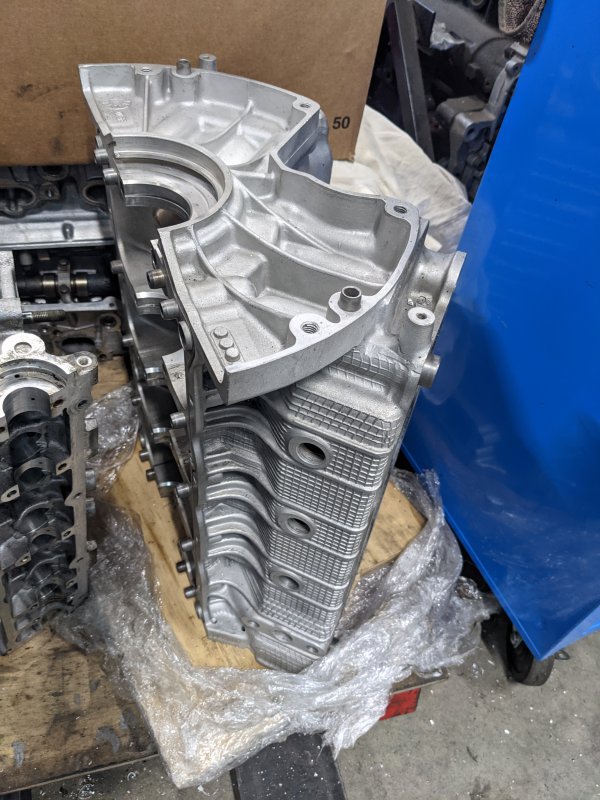

Frank had stuck into getting everything ready for me and it definitely has gotten there. Block was cleaned and back to its former glory. Here he also finished up with the heads and had everything package up for me ready to go!

Crank was hot tanked and journals were polished and all dimensioned checked for wear(as good as out of factory! Checked this myself too, prior to handing it(might not have been worth doing anything if it wasn't) over and after getting it back from the shop check the clearance for the brand new bearings.)

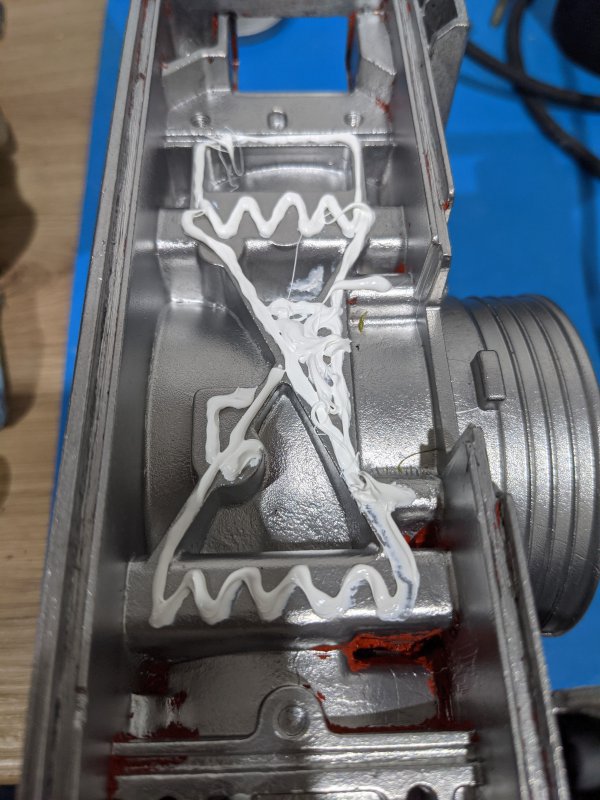

Oil galleries were drilled out, and all hardened carbon grit was cleaned up(I posted a photo earlier of the camera view of this gunk) and new plugs installed via the "Ferrari" method.

Block was jet washed, degreased, cold tanked and bead blasted; unsure of Frank's specific order of these tasks

De-carboned all pistons and cleaning all ring landings - preparation for ceramic and teflon coatings.

Liners all prepped and set for power honing for new piston clearances

All pistons and rods then fully assembled, with a reset on piston rings (got brand new Nissan VQ25 rings that were a spot on match to the originals as some were already broken or snapped when trying to be removed)

Re-tapped all holes except head bolts, I ended up doing this.

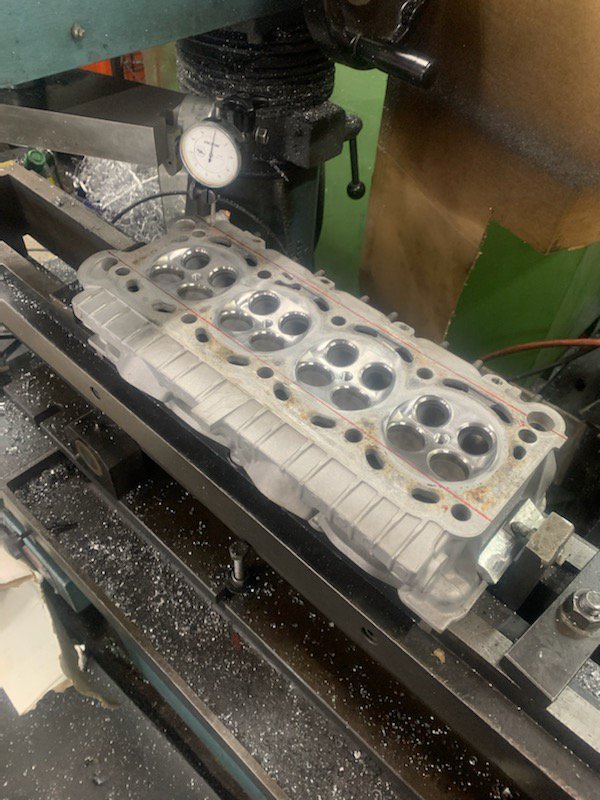

Heads were stripped, cleaned with intake and exhaust ports bead blasted. Then passed through the sergi jig, corrosion welded and passed through the jig again

Then cleaned, both valve seats and valves refaced. Power honed the valve guides, reset the valve stem protrusion.

New valve stem seals(I got through Maserati, but they are just Elring seals... nothing fancy) Spring rates checked.

Finally re-shimmed to match specifications and finally doing a vacuum check to be sure the valves are not leaking!

The only thing that Frank was afraid of bead blasting, was the cam box, and I agree with him. Any beads damaging the cam surface and it's trouble. I would need to seal these tight and let Greg blast the exterior (another job to be done another day!) Or to leave it as evidence to the history of it :|

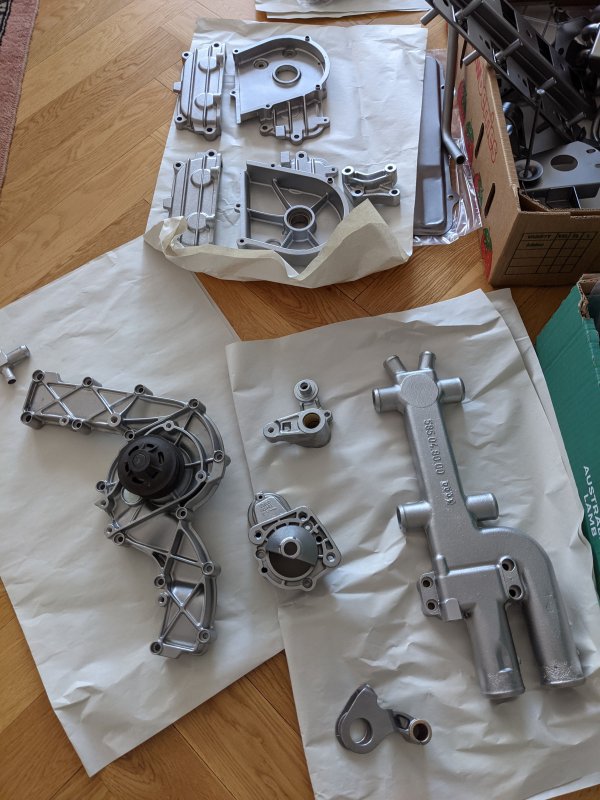

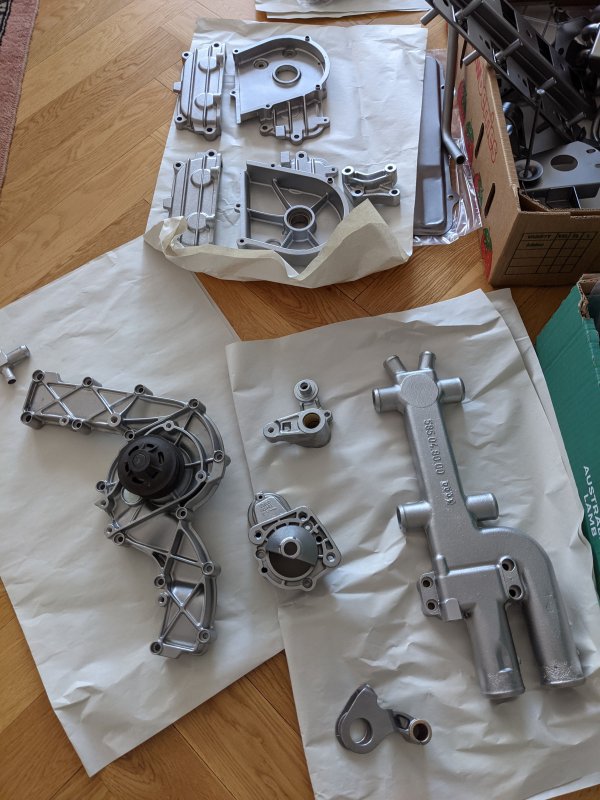

Next day; after a months worth of work! All the Hydroblasted bits were complete and ready for their next journey

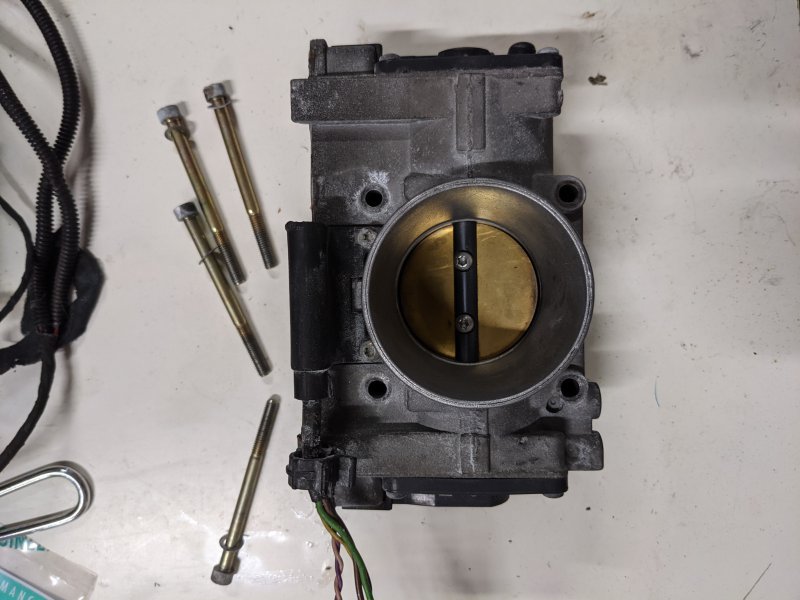

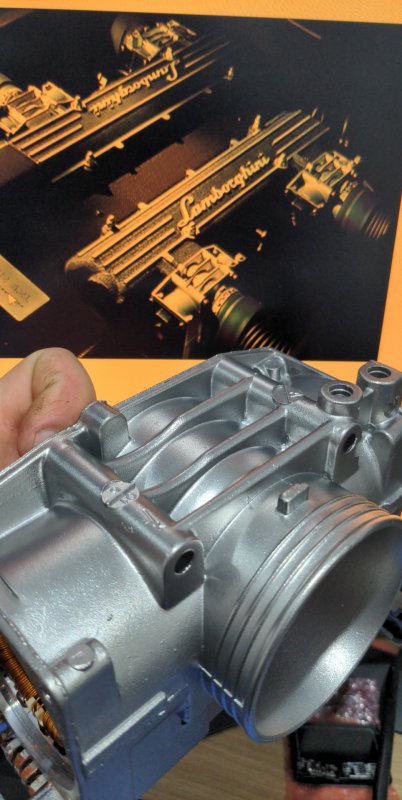

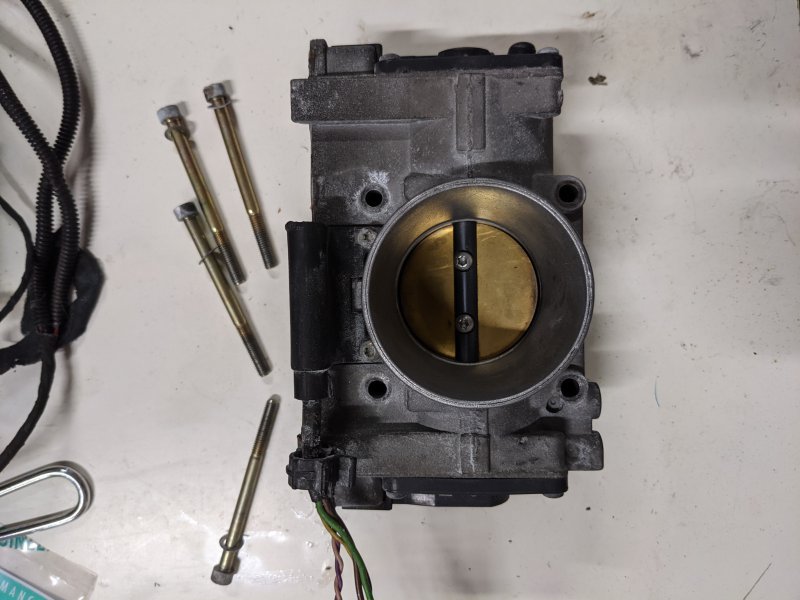

Greg had some trouble with dismantling the brake master cylinder and mentioned if I can dismantle it, he'll gladly get it done. It was as simple as pushing the spring in and turning it upside down for the pin to fall out of the exchange ports. And back it went along with the throttle body(and few other smaller bits I forgot about). This. was a disgusting mess(which I still haven't finished, ugh) I'll explain this in the next post

Anyway; here are

some one pretty pictures of perfect looking parts

Photo Maximum; I'll continue seeing as I'm a tad bored today, lol